Mastercam

Our Mission

To create software and services that solve the world’s manufacturing challenges.

Strength and Stability

For over 40 years, Mastercam has powered the world’s most demanding manufacturers. We build our software where it matters—on shop floors, in programming departments, and alongside the people who use it every day.

Our approach is simple: combine cutting-edge technology with real-world manufacturing expertise. We don’t just develop features in isolation—we solve actual production challenges our customers face. This direct connection to manufacturing reality is why over 450,000 installations worldwide trust Mastercam to drive their operations, from aerospace and automotive to moldmaking and beyond.

We stay ahead by staying connected. Every update, every feature, every innovation comes from listening to what you need to succeed. Because the best CAD/CAM software isn’t built in boardrooms—it’s built for the people who make things.

Market Reach

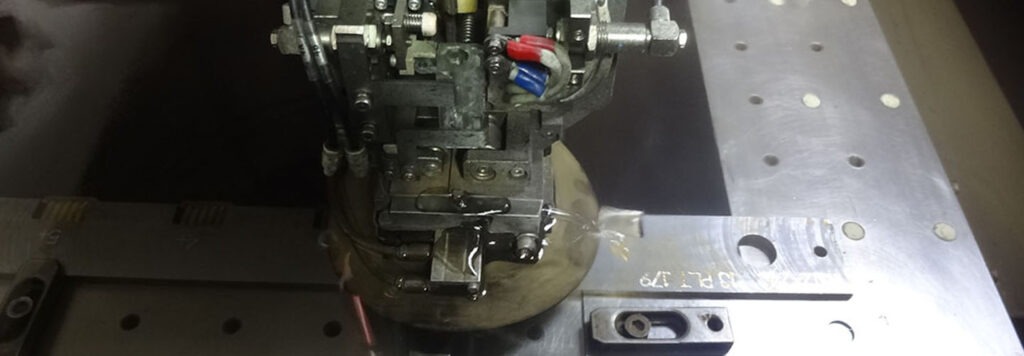

Mastercam provides solutions for designers and CNC programmers around the world, in a spectrum of applications including 2- through 5-axis routing, milling, and turning; 2- and 4-axis wire EDM; 2D and 3D design and drafting; surface and solid modeling; artistic relief cutting; and Mill-Turn. Customers range from one-person job shops to Fortune 100 manufacturers. With Mastercam, the same software that is used by corporations such as Boeing, IBM, and Sikorsky is still affordable enough for the small job shop. To ensure an ongoing supply of trained programmers and machinists, Mastercam is available to educational institutions at sizable discounts.

As our flagship product continues to grow and expand into new markets and technology, the company’s focus remains on our customers. Mastercam is committed to delivering solutions that support higher productivity and greater precision for the wide-ranging needs of manufacturing.

Success Stories

3D-Machine, Inc.

Before using Mastercam Lathe Custom Thread toolpath, producing a hoist drum—including machine set up, tooling, and machining—took at least 40 hours. With the CAM toolpath, 3D-Machine, Inc. produced the part in just seven hours.

Hi-Tech Machining Company

Hi-Tech Machining Company in Spartanburg, South Carolina has come a long way since its beginning in Robert Fowler’s backyard in 1987. Now a driving force in the manufacturing industry, Hi-Tech specializes in designing, machining, and repairing custom molds and parts for a wide variety of clients.

Transparency in Coverage

This link leads to the machine-readable files that are made available in response to the federal Transparency in Coverage Rule and includes negotiated service rates and out-of-network allowed amounts between health plans and healthcare providers. The machine-readable files are formatted to allow researchers, regulators, and application developers to access and analyze data more easily.