A Unique Team for a Unique Problem

Precision Manufacturing Solutions, Inc. generated a post working collaboratively with their local Reseller and Mastercam for the dual-toolhead Mazak Integrex III Series 11-axis milling and contouring CNC machine. The new post uses both toolheads to allow simultaneous cutting.

Quick Facts

- Product Used: Mill-Turn

- Industry: Aerospace & Defense, Medical, Job Shop

Project Details

- The Challenge: Generate a post for the dual-toolhead Mazak Integrex iii Series 11-axis milling and contouring CNC machine to allow for both milling and turning toolpaths to run at the same time.

- Benefits:

- Improves manufacturing productivity by reducing set-up time and consolidating manufacturing operations.

- Mastercam Mill-Turn allows simultaneous cutting operations from both of the machine’s toolheads.

- Revolutionary post incorporates both toolheads so that one toolpath no longer cancels out the other.

- Collaboration between CNC Software, the customer, and Mastercam Reseller resulted in a post adaptable to all Integrex iii Series operations.

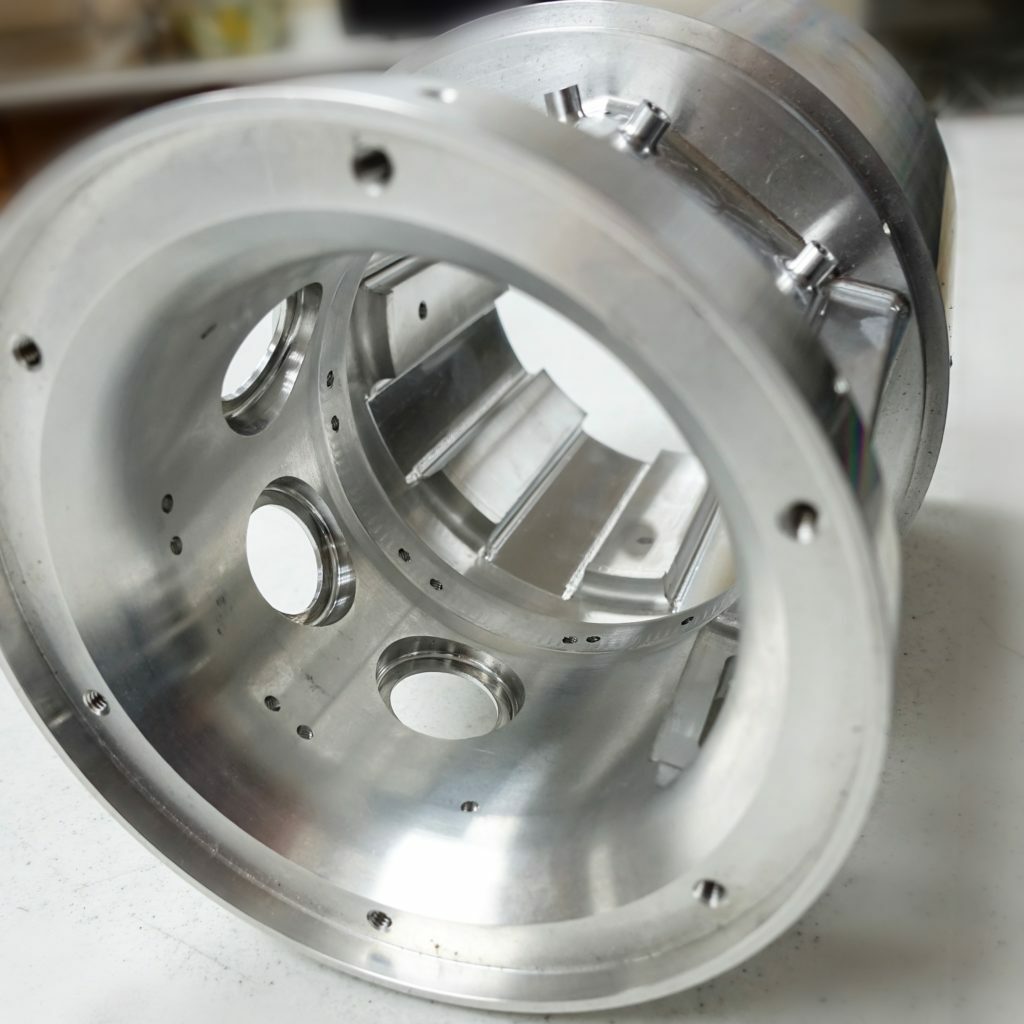

When clients in the medical, aerospace, and military industries need unique, precise parts that no one else can manufacture, they know to go to Precision Manufacturing Solutions, Inc. in Biddeford, Maine. Since 1962, Precision Manufacturing Solutions has been on the forefront of innovation in the manufacturing industry. Its shop is state of the art; its techniques are revolutionary; and its equipment is constantly being upgraded.

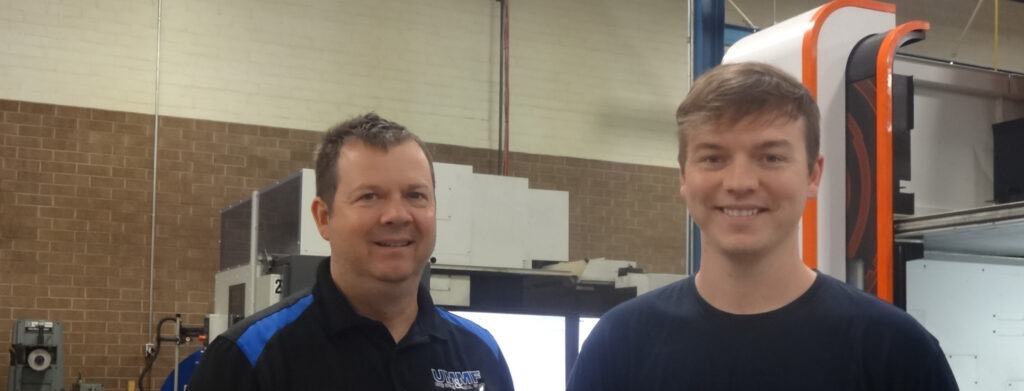

The shop’s Mazak Integrex iii Series 11-axis milling and contouring CNC machine is indispensable for the complex prototyping work for which Precision Manufacturing Solutions is known. Using the machine hasn’t always been straightforward, though. The Mazak’s dual toolheads operate separately and require different toolpaths. And, while the programmers have found Mastercam Mill-Turn to be invaluable in pushing the machine to its full potential, writing the post for this machine was proving to be a significant challenge, because one toolpath cancelled out the other. The top simply would not work with the bottom. Process Engineer Shaun McAlevey teamed up with Mike Slajka at Mastercam Reseller Cimquest, Inc. in Branchburg, New Jersey, along with Pedro Sanchez, Keith Goodrich, and Quanwen Du at Mastercam developer CNC Software Inc. to find a solution.

CNC Software built the post from the ground up, relying on Cimquest’s experienced staff for assistance. McAlevey tested each new version of the post, checking for issues and reporting on successes.

The team knew from the start that the project would be a complicated one. “We couldn’t take the old-style post from a new engine and just convert it to a new platform. We really had to develop the whole thing from scratch. It wasn’t a one-to-one conversion,” explained Sanchez.

As they continued to search for a solution, one of the team’s biggest concerns was the adaptability of the post. Sanchez said that finding a solution that could work for any customer was a matter of tailoring the post to work with the machine’s unique specifications. “If we go with how the machine needs to run, then it’s generic across the board and if we give it to another customer, it’ll run.”

All three parties dedicated as much time as possible to the project, but each had its own commitments. Cimquest and CNC Software had many other clients to help, and Precision Manufacturing Solutions had its usual orders to fill. The post was pieced together slowly but surely, over phone calls, emails, and meetings.

The resulting post, the Mazak Mark III, launched in September of 2018 after about six months of hard work. The post incorporates the two toolheads seamlessly, allowing simultaneous cutting from both. Luckily for Mazak users, the post can be adjusted to work with any machine on the same platform. Nothing like it exists, and its launch was met with high demand.

The Mazak Mark III post is a testament not only to the dedication and expertise of all the people involved, but to the willingness of each party to work with the others. Most, if not all, users of Mastercam know that they can rely on their local Reseller for technical assistance. Now, with the evolution of this post, it is abundantly clear just how hard Resellers and the staff at CNC Software will work to solve their problems.

CUSTOMER QUOTE

“I save a day or two when programming jobs just by using Mill-Turn.”

Shaun McAlevey, Process Engineer at Precision Manufacturing Solutions, Inc., Biddeford, Maine