Mastercam MultiAxis

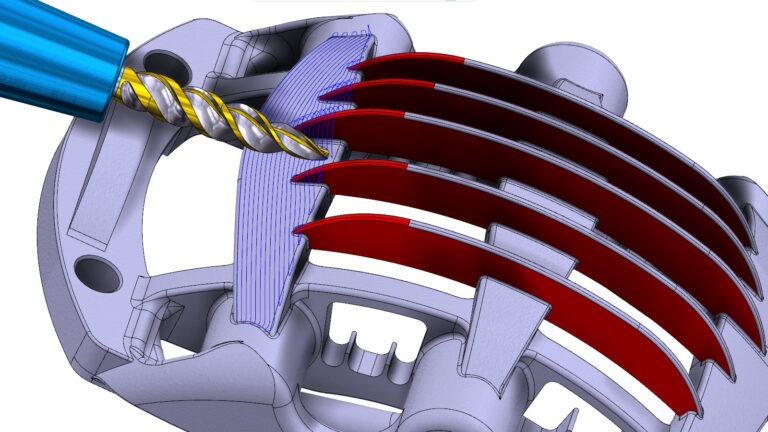

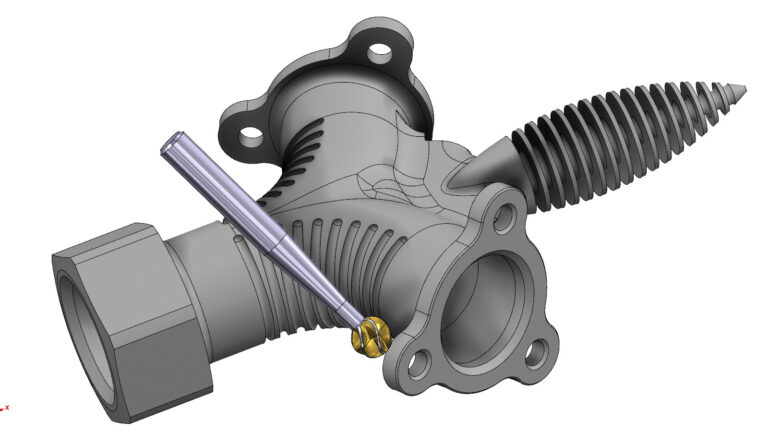

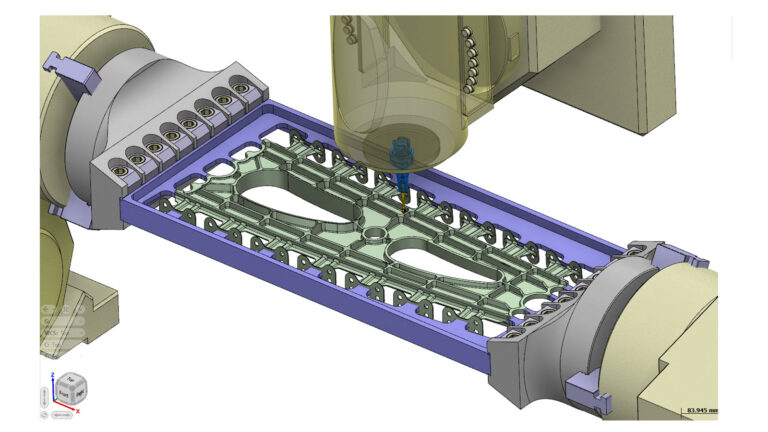

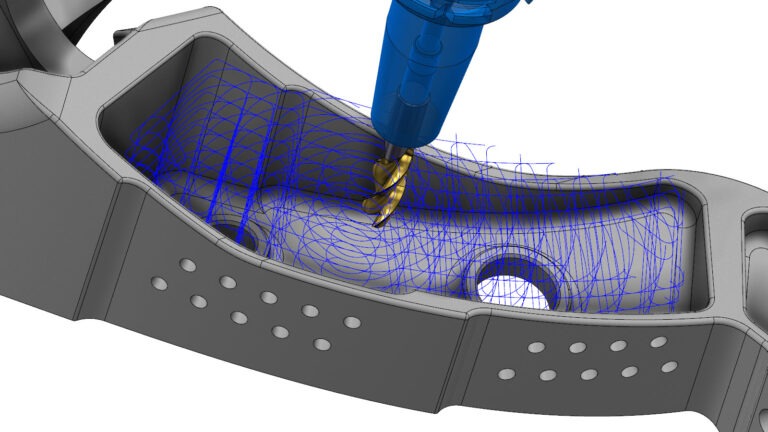

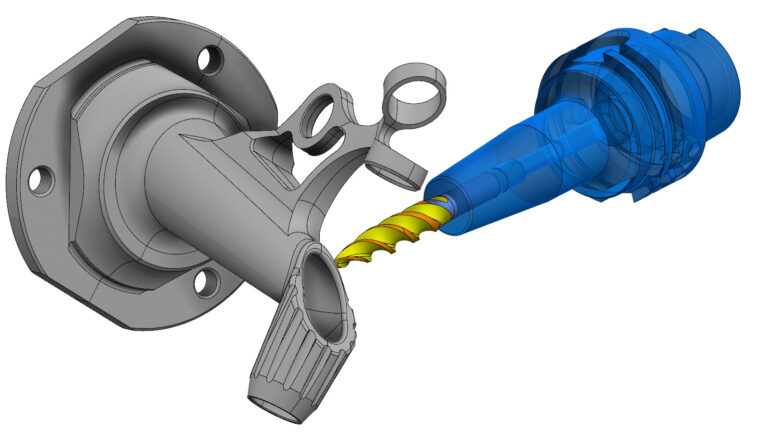

Simultaneous 4- and 5-axis machining capabilities with advanced toolpath strategies that deliver superior surface finishes and reduced setup times

Master Complex Geometries with Precision and Control

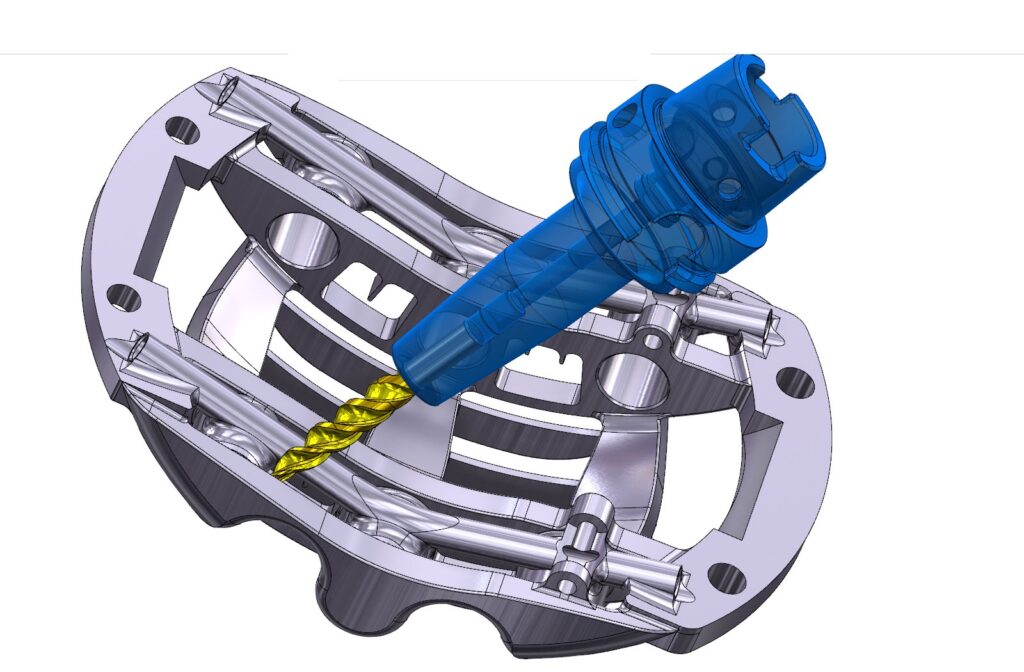

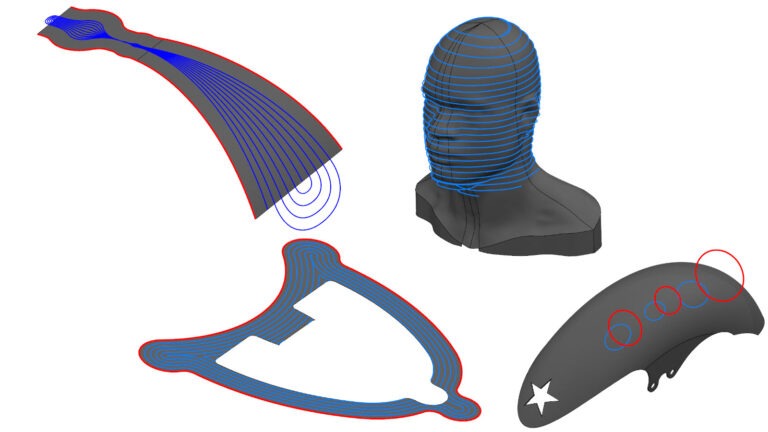

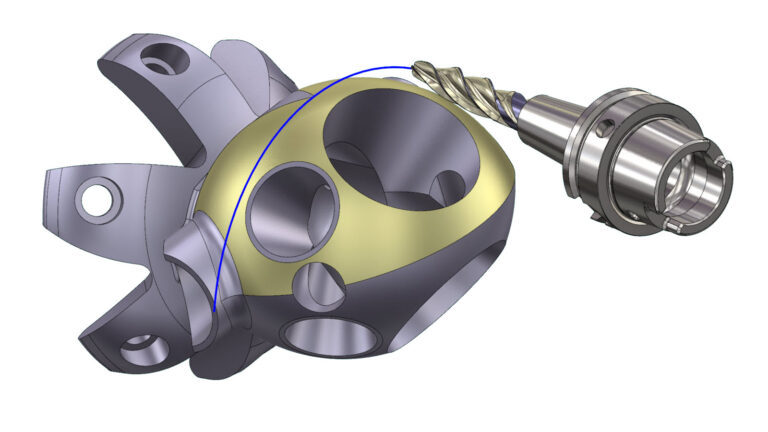

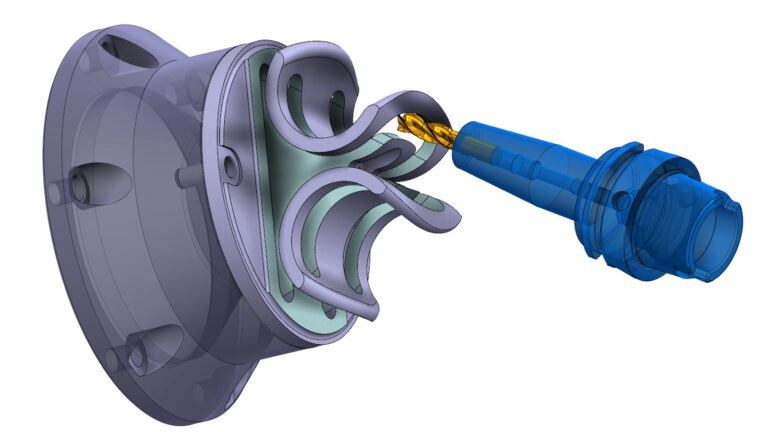

Mastercam Multiaxis offers a comprehensive range of multiaxis machining strategies—both basic and advanced—for simultaneous 4- and 5-axis operations. With complete control over cut pattern, tool axis control, and collision avoidance, you can achieve multisurface roughing and finishing with stock model awareness, advanced gouge-checking, and a 5-axis safe zone around your parts for the safest cuts in even the most complex operations.

From Setup to Finish: Streamlined Multiaxis Workflow

Multiaxis Machining 101: How It Works and Its Benefits

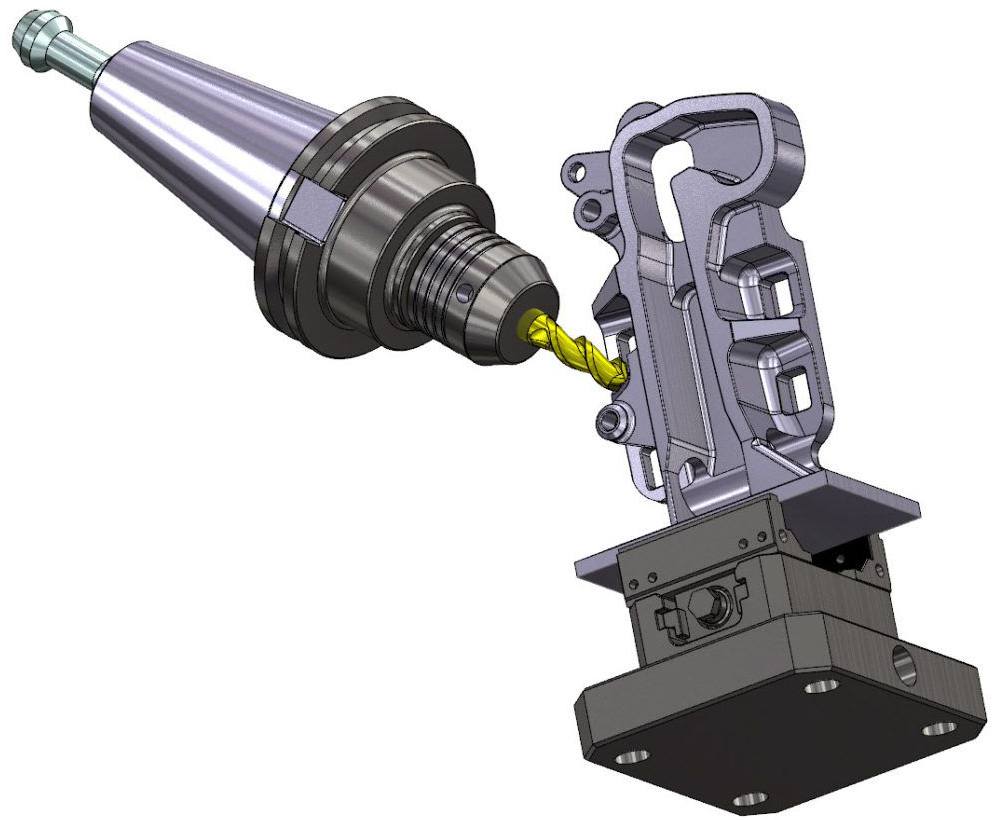

As automation and Industry 4.0 take the manufacturing world by storm, multiaxis machining is becoming essential for faster, more complex machining with less human labor. Multiaxis machines can move in four or more directions by adding rotary axes, enabling complete machining with only one setup and shorter tools while delivering superior surface finishes.

Features

Ready to Unlock Multiaxis Potential?

Transform your machining capabilities with simultaneous 4- and 5-axis operations. Fill out the form below to connect with Mastercam and discover how Multiaxis can revolutionize your productivity.