Gothic Architecture Powered by Mastercam

Blending spiritual devotion with modern machining to bring a Gothic vision to life in the mountains of Wyoming

Overview

Blending spiritual devotion with modern machining to bring a Gothic vision to life in the mountains of Wyoming.

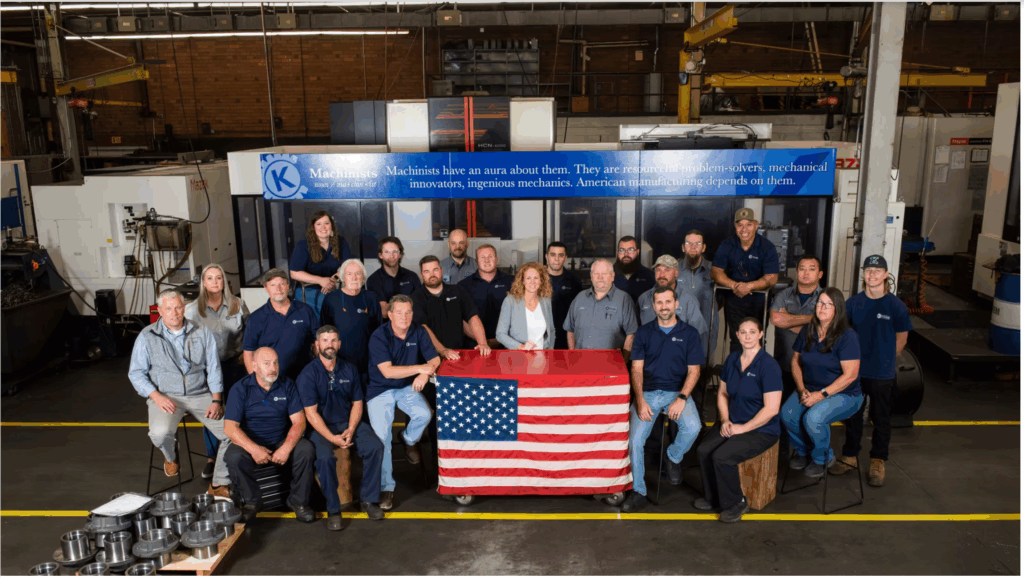

Above the sound of Gregorian chants, a CNC machine hums with purpose and precision. At 7,300 feet in the mountains of Wyoming, Carmelite Monks are building a medieval-style monastery with their own hands. Lacking funds and formal training, they did their research, turned to modern tools, and found a “divine” partner in Mastercam.

Project Details

The challenge

The Carmelite Monks dreamed of building a monastery that would stand for a thousand years – a sacred space of beauty, durability, and spiritual purpose. But when they contacted contractors, the cost was prohibitive.

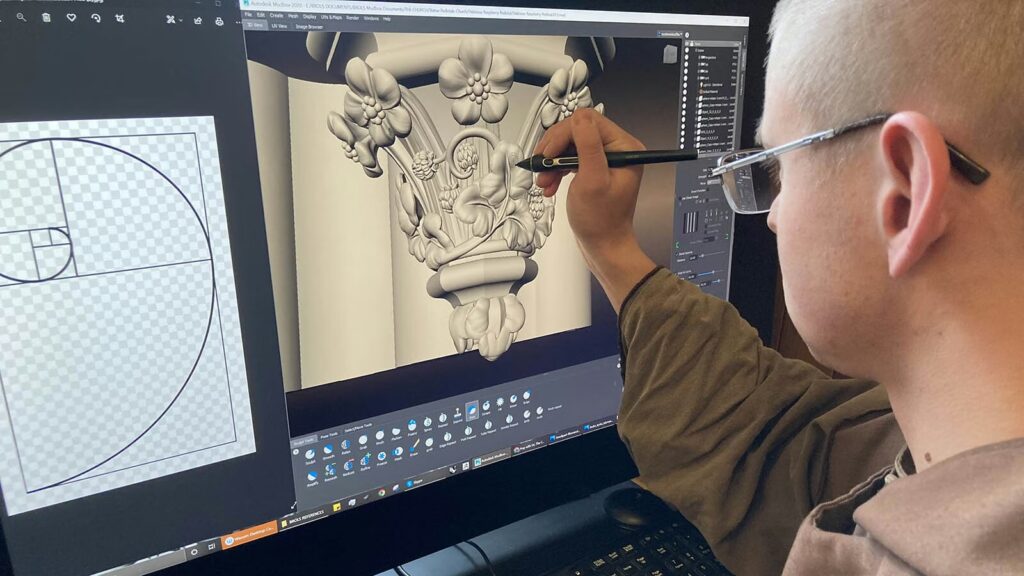

The monks decided to do it themselves. After testing other CAM platforms, they hit limitations. The other software just couldn’t execute the intricate geometries out of stone that the monks needed.

The solution

They discovered Mastercam with its advanced features, intuitive user interface, and deep user community. They were supported not only by the software itself, but by guidance from Mastercam and the expertise of channel partner DMG Mori Denver, who knows the benefits of Mastercam first-hand.

The impact

- Cost efficiency: By bringing stone carving in-house, the monastery avoided multimillion-dollar expenses.

- Significant time savings: A gargoyle that once took six months by hand can now be completed in a matter of days.

- Enhanced precision: Intricate carvings, such as stone foliage, demons with wings, and vine-covered arches, are created with amazing accuracy.

- Creative freedom: The advanced software enabled the monks to tailor every detail, achieving finishes that once required hundreds of toolpaths manually.

“What used to take an hour, now takes five minutes with Mastercam.”

Project details: The software behind the sacred work

Fifteen years ago, the Carmelite Monks of Wyoming sent out design plans for a monastery to general contractors. The responses? Eye-watering quotes, especially for the stonework. “We were looking at budgets that were astronomical,” says Brother Isadore Mary, who leads the stone-cutting operations. “The stonework, in particular, was a monstrous line item. So, we decided to do that ourselves.”

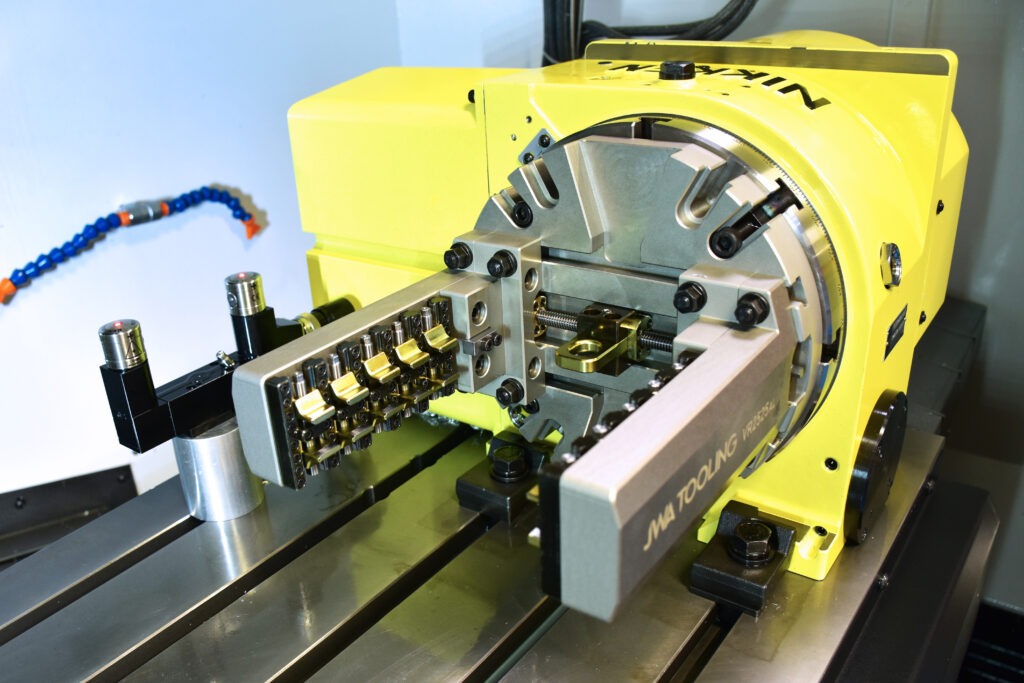

The monks initially used other CAM software, but as their designs became more ambitious and detailed, they began hitting hard limitations. The monastery’s architecture called for Gothic features like gargoyles, pinnacles, vine work, and stone flowers. “We needed a tool that could keep up with the complexity of our work,” explains Brother Isadore. “With Mastercam, we could do whatever we wanted. The level of detail and the ease with which we programmed it – we couldn’t achieve that before.”

Mastercam opened the creative floodgates. For example, a few months ago, the monks carved a highly detailed gargoyle from solid granite. The gargoyle perched on a window corner featured tight, complex spaces between its wings and under its neck. Using multi-axis machining, the team was able to program continuous, precise toolpaths that reached into every cavity without stopping or readjusting. The piece came off the machine needing no touch-up work at all. It was simply done.

With Mastercam’s advanced settings and 5-axis capabilities, the monks could achieve surface finishes and fine details they never thought possible. “What used to take an hour,” Brother Isadore says, “now takes five minutes.”

The building is symbolic. The monks say Gothic architecture is meant to draw the eye “up.” They believe that the three aspects of good architecture are functionality, durability, and of course – beauty.

“Our main job as monks is to pray for the world,” says Brother Isadore. “Everything else we do, including this stonework, is to support that prayer.”

The monks source their boulders from various stone quarries across the country, including Wyoming, Colorado, Kansas, and California. Every stone has a name, like #538, and the monks know exactly where each one belongs. Typically, about 10 monks are involved in the construction of the monastery. The main monastery buildings have been completed and have been in use for the past six years. The final and most intricate phase is the chapel, which remains under construction. As the most ornate and complex part of the entire structure, it represents the culmination of the monks’ craftsmanship. Overall, the project is now approximately three-quarters complete.

They want to build something that will be standing a thousand years from now. And with Mastercam, there is no limit to their creativity. Every embellishment, be it a flower or a gargoyle to ward off demons, can be dramatized in stone.

Quick facts

- Product used: Mastercam Mill 3D | Multiaxis | CAD/CAM

- Results: Cost savings | Time per part reduced from hours to minutes | Unlimited creativity