As a CAM software engineer who has dedicated years to pushing the boundaries of CNC programming, I can honestly say that what we are bringing to EMO Hannover 2025 represents a huge leap in manufacturing technology. From September 22-26 at the Hannover Fairgrounds, we’ll be showcasing projects that have fundamentally redefined what is possible in precision manufacturing.

EMO—recognized as the world’s premier trade fair for production technology—has been the cornerstone of manufacturing innovation for over seven decades. This year’s event promises to be transformative, and our participation demonstrates how advanced CNC programming solutions are revolutionizing the intersection of artisanal craftsmanship and industrial efficiency.

Two projects in particular have pushed our engineering team to the absolute limits of what’s achievable with modern CAD/CAM technology. These are not just demonstrations—they are proof of concept for manufacturing’s future.

The World’s First Hollow Body Titanium Guitar

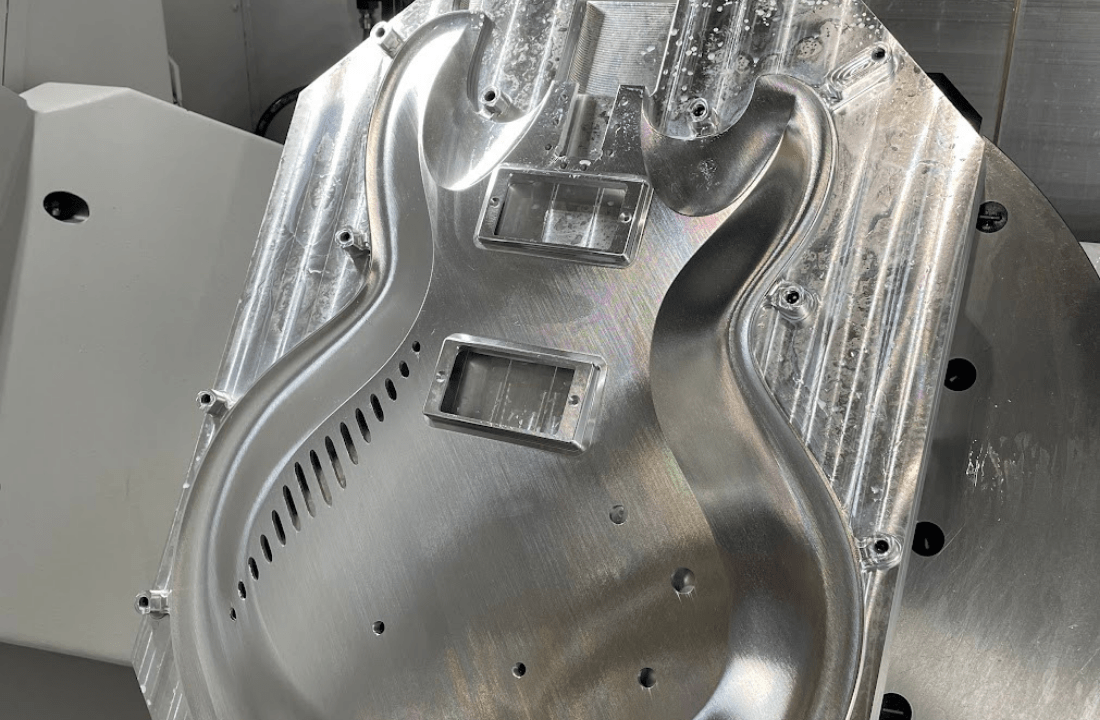

When legendary guitar designer Dean Zelinsky, the pioneer behind Dean Zelinsky Private Label and a true rock star in the world of luthiery approached us with his vision to machine an entire guitar from titanium, my initial reaction was skepticism. Creating a fully functional instrument from aerospace-grade titanium while maintaining the sonic characteristics of traditional wood construction? I had never heard of it being done before. But that is exactly what we accomplished.

This revolutionary collaboration between Dean Zelinsky Private Label, Mastercam, DN Solutions, Iscar Metals, and our key partners resulted in something extraordinary: a three-piece titanium guitar (front body, back body, and neck) that exemplifies aerospace-grade precision with a staggering 96.5% material removal rate.

Engineering Excellence in Every Detail

The technical specifications tell the story:

- Front Body Engineering: Starting with a 78.7 lb. solid titanium billet, we achieved a final weight of just 2.6 lbs.—representing 96.65% material removal. The internal architecture features honeycomb ribbing that delivers structural integrity without mass penalty, while precisely machined magnetic bosses enable seamless snap-fit assembly. All electronics and hardware mount to the front body, making it fully functional as a standalone unit.

- Back Body Complexity: Mirroring the front’s sophisticated geometry, the back body incorporates sculpted curves and structural ribbing machined from an identical 78.7 lb titanium billet. We integrated space for Dean’s iconic spider engraving and partner logos, requiring multi-axis programming of exceptional precision.

- Neck Innovation: The one-piece neck design represents perhaps our greatest technical achievement. Featuring integrated CNC-machined frets, Dean’s patented ZGlide friction-reducing surface textures that reduce contact by 70%, and a dovetail mounting system ensuring perfect body alignment. At 96.48% material removal, this component demonstrates precision weight optimization at its finest.

- Manufacturing Excellence on the DVF8000T: All machining operations were executed on DN Solutions’ DVF8000T—a full 5-axis HSK100 powerhouse delivering 49.6 HP and 488 Nm of torque. Working in our Manufacturing Lab with the Prototype Engineering Team, every toolpath was meticulously programmed using Mastercam’s advanced 5-axis capabilities, with verification handled by Vericut’s Force module. The cutting strategy employed Iscar tools and Haimer holders for optimal chip control and surface finish, while Lambda Function’s real-time tool life monitoring provided intelligent spindle uptime management. One programming error could have cost us a $15,000 titanium billet—precision was non-negotiable.

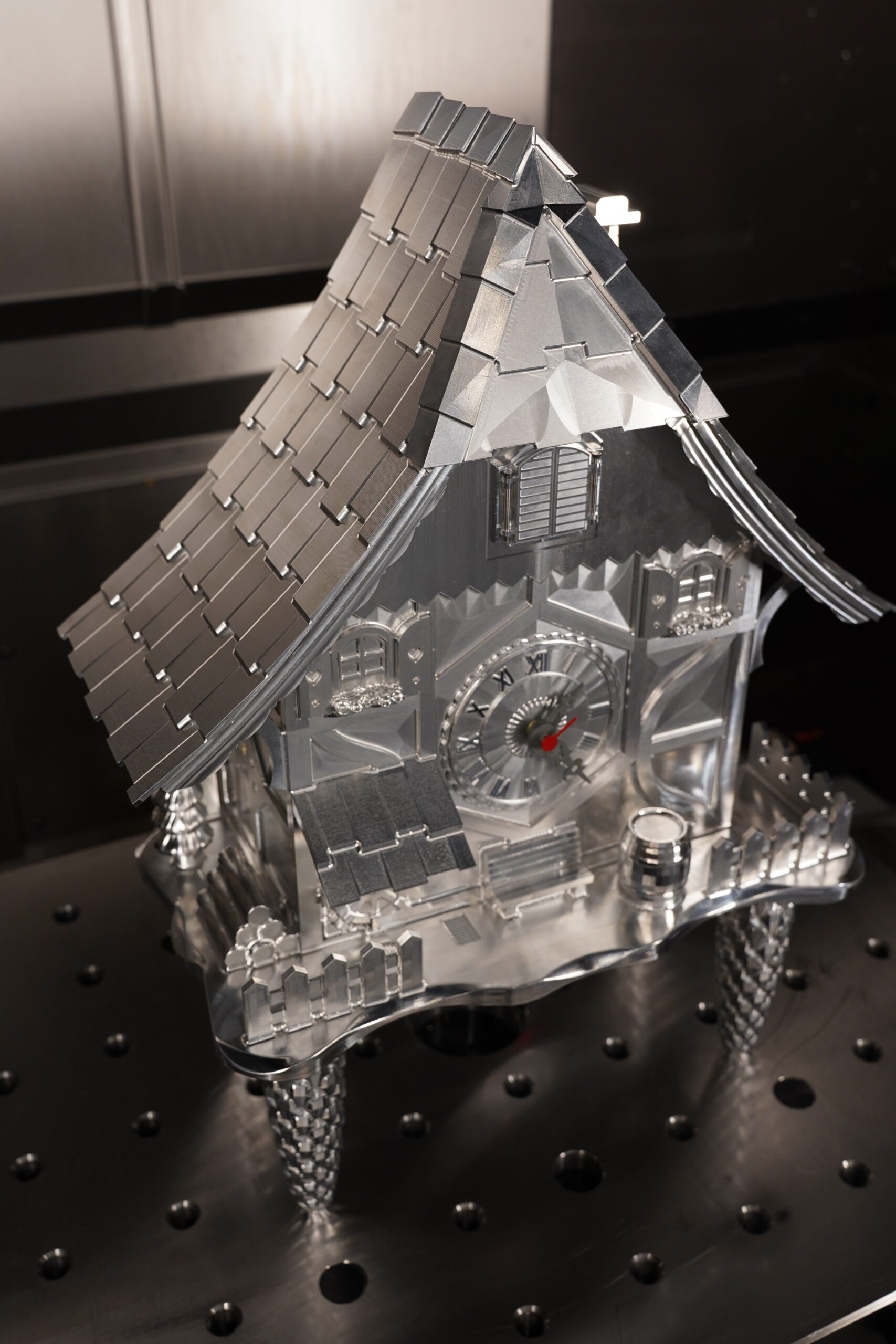

The Hermle Cuckoo Clock: Tradition Reimagined Through Technology

Our collaboration with Hermle Machine Tools on the Cuckoo Project pushed different boundaries entirely. Over eight intensive days at Hermle’s German facility, I worked alongside their application engineers to machine an aluminum cuckoo clock of unprecedented complexity—geometry that their seasoned aerospace engineers initially deemed impossible.

Starting with a 300x300x160mm solid aluminum block, we reimagined the classic Black Forest timepiece through advanced 5-axis machining, demonstrating sophisticated geometry handling and collaborative engineering excellence.

Advanced CAM Strategies in Action

This project showcased Mastercam’s most sophisticated capabilities:

- Convert to 5-Axis Functionality: Essential for driving toolpaths on mesh-based geometry, particularly around the intricate rooftop architecture and complex undercuts.

- Clean Core Algorithms: Navigated tight spaces like the organic tree forms beneath the roof, enabling precise tool movement in narrow cavities while maintaining collision avoidance.

- Unified Toolpath Technology: Combined parallel and guided cutting methods for superior surface finishes and tool control around architectural details.

- Multi-Axis Roughing: Efficiently removed bulk material while maintaining practical shop-floor execution parameters.

- Full 5-Axis Deburring: Leveraged complete machine kinematics and tilt control for consistent edge finishing across tall, narrow features.

The programming complexity required OptiRough and stock model exports to manage the job in executable stages, enhancing toolpath efficiency and stock awareness. Tool Axis Control took priority in constrained areas, reducing collision control dependency while enabling intelligent tool movement.

Mastercam 2026: Live Demos

What made these projects possible is our latest release: Mastercam 2026, featuring advanced productivity tools and new features that enable machining precision of the most complex components. In addition to highlighting all the new features in the 2026 release, here are the three new products we will be demonstrating at our booth:

Mastercam Copilot: AI-Enabled Programming Assistant

Discover Mastercam Copilot: your intelligent, AI-powered assistant built to simplify complex programming. From natural language commands to contextual help and hands-free interaction, Copilot transforms how manufacturers navigate Mastercam—see it live at our booth and experience smarter manufacturing firsthand!

Mastercam Probing: Intelligent Setup Verification

Programming spindle-mounted touch probes directly within Mastercam has revolutionized my approach to setup verification. The system automatically generates and inserts machine-independent G-code directly into NC programs, improving part quality, and reducing setup time while eliminating manual processes.

Mastercam Deburr: Precision Edge Treatment

This comprehensive solution for efficient, precise deburring and edge treatments integrates seamlessly with existing Mastercam workflows. The unprecedented control over deburring operations, reduced manual labor requirements, and optimized tooling resource utilization significantly improve part quality. The solution leverages deburr cycles efficiently in 3-axis environments without requiring a Multiaxis license.

Join Us at EMO Hannover 2025

If you are looking for inspiration, real-world solutions, and a team that is as passionate about machining as you are visit us at Hall 6, Booth A36, September 22-26.

For those unable to attend, follow us on social media channels. We will be capturing everything: cutting videos, behind-the-scenes programming sessions, and real-time demonstrations of advanced CNC programming techniques.

See you at EMO!

Contributed by Dave Miller, Manager of Product Marketing Engineering