In the world of machining, precision is everything. Whether you’re producing aerospace components or custom molds, even the smallest deviation can lead to costly rework or scrap. That’s where Mastercam Probing comes in—a fully integrated add-on that automates measurement, alignment, and inspection tasks directly on your CNC machine.

Let’s explore what Mastercam Probing is, how it works, and the top five features and benefits that make it a game-changer for more efficient machining workflows.

What is Mastercam Probing?

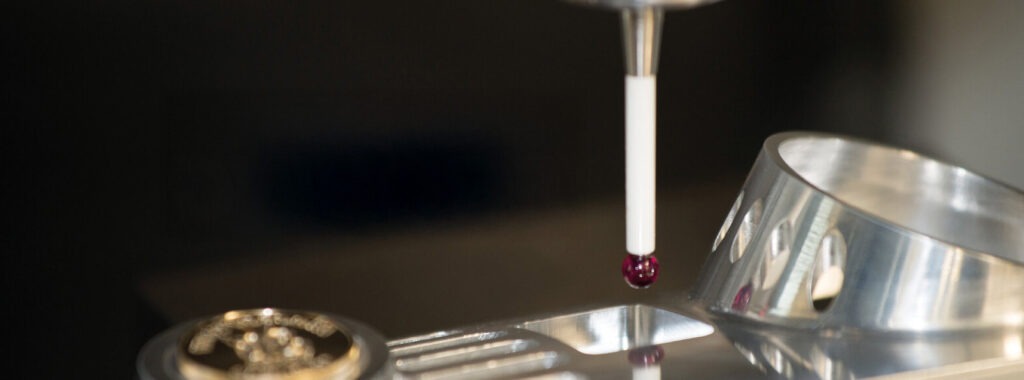

Mastercam Probing uses a touch-trigger device (probe) mounted on a CNC machine to perform automated tasks such as:

- Workpiece setup and alignment

- Tool measurement and breakage detection

- In-process and post-process inspection

By integrating probing into your workflow, you can dramatically improve accuracy, reduce setup time, and support lights-out manufacturing—where machines run unattended with confidence.

Common Applications of CNC Probing

Here’s how probing is typically used in a CNC environment:

Workpiece Setup & Alignment

- Automatically locate part edges, centers, holes, and features.

- Set work coordinate systems (G54–G59) with high precision.

- Compensate for skewed or misaligned parts.

Tool Setting

- Measure tool length and diameter using a tool setter probe.

- Automatically update tool offsets in the controller.

In-Process Inspection

- Check part dimensions mid-cycle to ensure tolerances are met.

- Detect tool wear or breakage in real time.

Post-Process Inspection

- Verify final part dimensions while still fixtured.

- Log measurement data for quality control and traceability.

Top 5 Features of Mastercam Probing

Mastercam has fully embraced probing with its integrated Probing toolpaths, making it easier than ever to program and simulate probing operations. Here are the standout features:

1. Automated Workpiece Setup

Quickly locate edges, bores, bosses, and corners. Assign work offsets (WCS) based on probe data—no manual edge-finding required.

2. Tool Measurement & Breakage Detection

Measure tool length and diameter automatically. Detect broken tools before they ruin a part, using built-in macros.

3. In-Process & Post-Process Inspection

Run checks mid-cycle or after machining to verify critical dimensions. Trigger alarms or offset updates if parts are out of spec.

4. Ease of Use & Implementation

Mastercam Probing utilizes the same probing cycles already installed on your machine.

5. Simulation & Collision Detection

Visualize probing moves in the Mastercam Simulator. Avoid crashes and invalid moves with built-in collision detection.

Compatibility & Machine Support

Mastercam Probing works seamlessly with popular hardware and controllers:

- Probing Systems: Renishaw, Blum-Novotest, and more.

- Controllers: Fanuc, Siemens, Heidenhain, Haas, etc.

- Post-Processor Support: Custom output for G65, G31, Renishaw macros, Siemens cycles, and others.

Who Benefits Most?

Mastercam Probing is ideal for:

- Both low and high-volume shops utilizing the probe for both “one off” parts but also incorporating it into their production process to take the manual intervention out.

- Aerospace and medical manufacturers working with tight tolerances.

- Mold and die shops verifying electrode alignment and surface references.

Ready to improve your machining workflow?

Mastercam Probing lets you program your touch probe using the same methods you already know. It creates clean NC code and fits into your existing process.

Use it to cut down setup time, get better part accuracy, and run jobs without constant supervision. It’s a practical addition to your machining toolkit. Contact your Mastercam Representative to learn more or get pricing information.