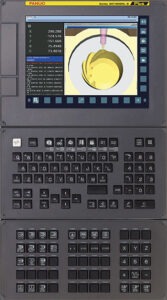

Post processor unlocks faster and more accurate “art to part” FANUC CNC capabilities

December 1, 2020 (Tolland, Conn.) – CNC Software, Inc., developers of Mastercam CAD/CAM software, and FANUC America, a leading factory automation solutions provider, introduce a new post processor designed to optimize 5-axis capabilities in FANUC CNCs. The post-processor allows advanced machine tool operators to reduce their cycle times while boosting part accuracy, particularly for CAD/CAM generated 5-axis simultaneous contouring part processes.

“Growing our relationship with FANUC was an opportunity that would continue to benefit our customer base and enhance our post processors. Working with the FANUC team was beneficial on the creation of the new FANUC 5-axis post to run the FANUC 30i-B and 30i-B Plus series controls. This collaboration ensured that we provided FANUC’s best methods of running their controls. Without a doubt, our new 5-axis post processor will bring the highest productivity gains to machine tools for customers,” says Mastercam Post Department Manager Pedro Sanchez, Jr.

A growing number of manufacturing industries, such as aerospace, medical, and mold and die job shops, are incorporating 5-axis simultaneous processing in their operations. By optimizing FANUC CNCs with Mastercam’s new post processor, machine tools will be able to produce parts, modeled in the CAD system, more precisely.

“For 5-axis simultaneous contouring, a quality CAD/CAM system is critical,” says Rick Schultz, Aerospace Program Manager for FANUC America. “FANUC has worked closely with CNC Software to make it easy for programmers to create optimal toolpaths using the advanced algorithms available in the 5-axis Milling Standard Package for FANUC’s 30i-B and 30i-B Plus Series controls.”

Key functions of this post processor are:

- Table/Table (AC/BC/Nutating) Support.

- Rotary and Vector Programming.

- Artificial intelligence contour control (G05.1) Positioning Accuracy (R1 – R10).

- Workpiece setting error correction (G54.4P1 – G54.4P7).

- Tilted Working Plane Command (G68.2) with Controls tool axis direction (G53.1).

- Feature coordinate system setting by Euler’s angles, Roll-Pitch-Yaw, setting by two vectors, setting by tool axis direction.

- Tool center point control.

- Type 1 Rotary output (G43.4) /Type 2 Vector output (G43.5).

- Work offset support matching control capabilities (G54 – G59 / G54.1 P1 – G54.1 P300).

- Drilling Cycles (G89, G74, G82, G81, G83, G73, G84, G85, G86, G76).

“This new Mastercam post processor unlocks the full potential of machine tools that come with the 5-axis Milling Standard Package,” explains Schultz. “Shorter cycle times with better path accuracy and mirror surface finishes will set a new standard for machining with Mastercam generated code.”

For more information about Mastercam, please visit www.mastercam.com.

For more information about FANUC, please visit www.fanucamerica.com. For information on their 5-axis solutions, visit https://www.fanucamerica.com/solutions/applications/five-axis-machining.