Mastercam Course Descriptions

Classes and Pre-requisites

One of the best ways to hone your skills is through our instructor-led training classes. We offer in-person and live virtual instruction to ensure you get the training you need in the right environment.

Duration

4 days

Prerequisite

Basic PC skills and general CNC mill setup and operation knowledge

Pre-class Prep Download

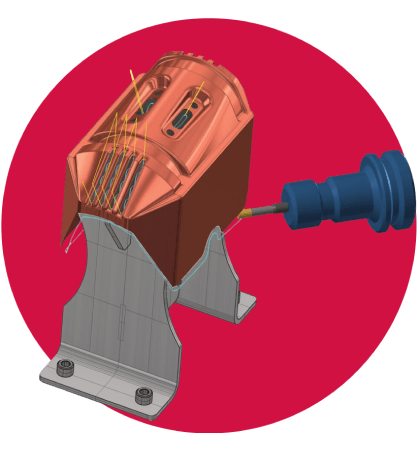

Instructors will mentor you in the basics of Mastercam to create 2.5D toolpaths. Students will learn from instructor lead exercises then perform student exercises covering icon functions, geometry and toolpath creation that will lead you to programming many different parts from start to finish.

Students will build upon the foundational principles by working on over 40 different real world part files to develop their skills. Students will be able to create and work with wireframe geometry and import Solid models for tool path creation in drilling, advanced pocketing, helical entry and the basics of dynamic milling.

Lastly, you will be able to program rotary axis substitution parts and index units.

Topics Covered

- Mastercam Interface and layout

- Creating/Modifying 2D wireframe geometry

- 2D drafting (notes, dimensions, etc.)

- Transforming geometry (rotate, scale, etc.)

- Levels control

- Preparing to Machine – machine definition and properties

- Machine Group Setup – stock setup, workholding tools

- Tool Path Utilities – toolpath manager, verify, back plot and posting

- 2D contouring, pocketing, and drilling

- Chaining basics

- Tool control (ramping, lead in/out)

- Helical entry

- Dynamic Milling – advanced contouring and pocketing

- Advanced drilling

- Work offsets

- Rotary axis substitution

- Indexing

Duration

3 days

Prerequisite

Mastercam Mill Essentials

Instructors will mentor students to create 3D toolpaths. Students will learn from instructor lead exercises then work through over 60 student exercises to create and edit complex surfaces and curves, then program them using a variety of efficient 3D toolpaths with a focus on High Speed and Legacy toolpaths. In addition, students will learn to use stock models and apply different workholding applications, gap settings, tool boundaries, and gouge checking.

Topics Covered

- Creating/Modifying surfaces

- Creating 3D curves

- Surface Utilities

- Stock Model applications

- Workholding applications

- 3D wireframe contouring machining

- Legacy 3D surface machining

- 3D High Speed surface machining

- Toolpath filtering and tolerance settings

- Gouge checking

- Tool boundaries

- Cut depths

Duration

3 days

Prerequisite

Mastercam Mill 3D

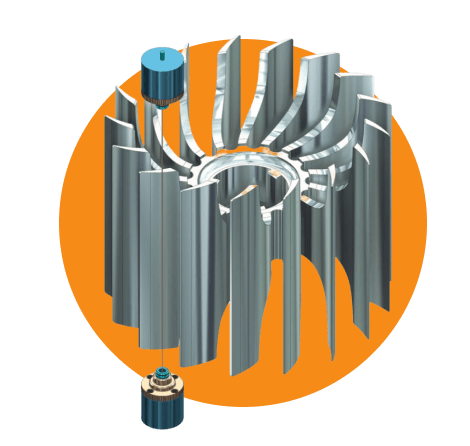

Instructors will continue mentoring students by building upon our Mill 3D class, to program essential 4 & 5-axis parts. Students will learn from instructor lead exercises then work on 40 different student exercises covering simple to complex roughing and finishing toolpaths. Important techniques of using containment boundaries, geometry applications, and tilting strategies will be covered.

Topics Covered

- 4 & 5-axis overview

- Machine types/axes

- Curve 5-axis

- Swarfing

- Flowline

- Multi-surface

- Drilling

- Unified Toolpaths

- Pocketing

- Trim to Stock

- Rotary 4th

- Deburr

- Circle Segment

Duration

2 days

Prerequisite

Mastercam Mill Essentials

Pre-class Prep Download

Instructors will mentor you in creating Mastercam 2-axis lathe toolpaths along with C&Y axis milling toolpaths. Students will learn from instructor lead exercises then work on over 30 different student exercises covering 2D wireframe then importing and manipulating Solid models for tool path creation for facing, drilling and rough & finish turning. Last, students will program several C & Y axis parts with live tooling. For each program created, you will post g-code, back plot and verify.

Topics Covered

- Mastercam interface navigation basics

- Lathe Planes and Align to Z

- Chaining

- Geometry creation & importing

- Turn Profile Creation

- Common toolpaths- facing, drilling, rough & finish turning

- Tool libraries

- Plane setup

- Dynamic Turning Toolpath

- Prime Turning Toolpaths

- C Axis toolpaths

- Wireframe / 3D Custom Tools

Duration

2 days

Prerequisite

Basic PC skills and general CNC Wire EDM setup and operation knowledge

Learn the basics of the Mastercam CAD and drafting tools, as well as the tools and techniques specific to creating and managing efficient wirepaths. 2-axis contour and 4-axis synchronization, multiple contour, custom lead-in and lead-out, tab creation, and verification are some of the subjects discussed.

Topics Covered

- Wirepath basics

- Contour chaining concepts

- Advanced editing concepts

- No core toolpaths

- 4 axis toolpaths

Duration

4 days

Prerequisite

Basic PC skills and general CNC Router setup and operation knowledge

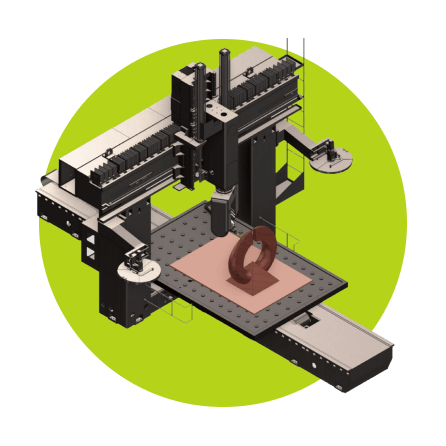

Instructors will mentor you in the basics of Mastercam interface navigation , geometry and tool path creation, leading you to program many different parts from start to finish. You will learn the foundational principles of basic 2½ axis tool paths and build upon them by programming many real world examples to develop your abilities. Upon course completion you will be able to create, manipulate and import basic 2D wireframe and Solid models for tool path creation in drilling cycles, contouring, pocketing, nesting and tabbing.

Topics Covered

- Mastercam Interface and layout

- Creating/Modifying 2D wireframe geometry

- Basics of Solids

- Transforming geometry (rotate, scale, etc.)

- Levels control

- Preparing to Machine – machine definition and properties

- Tool Path Utilities – toolpath manager, verify, back plot and posting

- 2D contouring, tabbing & pocketing

- Block drilling

- Engraving

- Chaining basics

- Tool control (ramping, lead in/out)

- Patterns

- Nesting

- Work offsets

- Standard Aggregate tool heads (90 degree heads)

Duration

2 days with Mill Essential prerequisite

Prerequisite

Basic understanding and reading of mechanical drawings. Mastercam Mill Essentials.

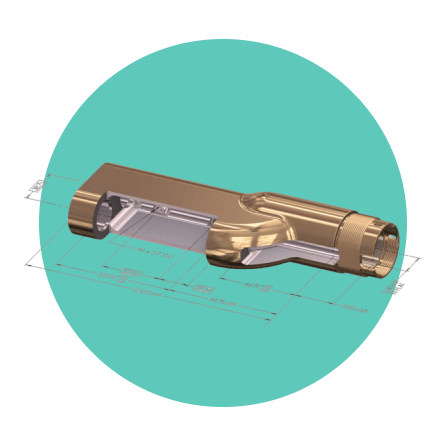

Mastercam Solids Design course enables you to create and modify various types of geometry including wireframe, solids and surfaces. Then create part fixturing, soft jaws and work pieces through multiple student exercises in order to prepare them for toolpaths or save as a file for 3D printing. In addition, you will learn to create basic sectional & auxiliary views then identify and fix given geometry issues. Lastly, review proper dimensioning methods and apply dimensions to multiple exercises.

Topics Covered

- Levels

- Solids creation

- Solids edit/modify

- Solids pattern/impressions

- Model prep functions

- Surface from Solids

- Analyze & attributes

- Geometry transform

- Merge

- Saving for toolpaths or 3D printing

- Identify & fix geometry issues

- Dimensioning