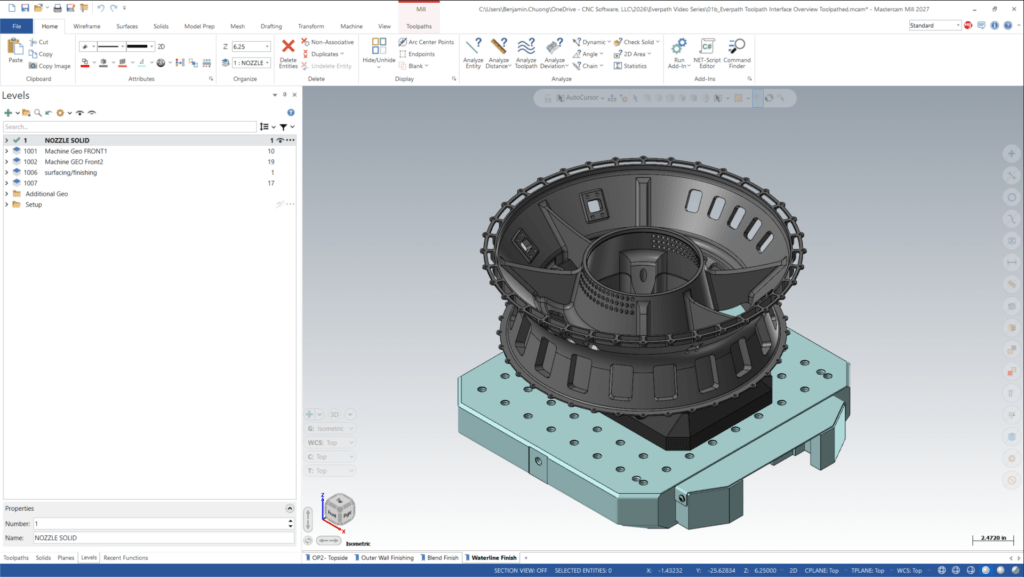

Welcome to Mastercam 2026! The latest release is here to elevate your machining experience. With feedback from users and shops worldwide, we built upon our past advancements and are excited to bring you our most intuitive interface yet.

Mastercam 2026 includes various improvements allowing you to increase productivity, complete tasks quicker, more accurately, all while saving time and resources.

Let’s check out the top 5 new Mastercam 2026 productivity features and see how they can improve your shop’s performance.

1. Enhanced Solid Hole Functionality

Mastercam 2026 introduces a new way to create holes in solids. These features have been organized into three panels: Geometry Selection, Hole Style, and Advanced, allowing you to design different types of holes in a solid with precision and control through new features and functions.

Solid Hole Void Support is now available. When you create a hole for a hole-making toolpath, the new Include Voids checkbox provides selection control of the voids between hole segments. The resulting single-hole form includes hole segments that are collinear to the selected hole, in addition to the voids between them, compromising a single hole form. When the Include Voids checkbox is unchecked, collinear holes with voids between them are considered individual hole forms.

2. Loft Surface Creation Enhancements

When using wireframe geometry to create a lofted surface, you now have more controls which allow for smoother flow and blending of surfaces. Automatic alignment of chain directions allows you to window select chains without worrying about their directions which saves time when selecting multiple chains.

Surface tangent matching ensures that loft surfaces blend smoothly into existing adjacent surfaces.

Guide curves are a new way of synchronizing flow across chains of curves and eliminates the need to manually break up groups of chains to sync curves to your desired flow. Dynamic sync options have been reorganized and updated.

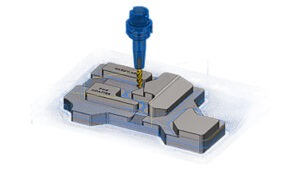

3. 3D HST Critical Depths for OptiRough

For Mill 3D and Router 3D users, Critical Depths can be used to machine critical flat areas while performing simultaneous 3-axis machining. When creating a toolpath, Critical Depths gives you control over flat-area machining, eliminating the need to add additional flat-area operations at critical depths. Critical Depths in Dynamic OptiRough is only available on the stepdown move of the toolpath.

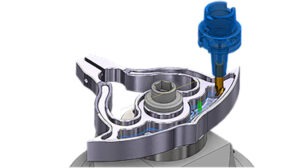

4. Dynamic Mill and OptiRough Tapered Helix Entry

A new checkbox for the Helix Only entry method lets you produce a tapered helix. Using a tapered helix to enter a pocket promotes better chip evacuation, coolant/air access, and is more efficient than a cylindrical helix. Achieve better tool life and more efficient toolpath creation.

2D Mill users will benefit from this feature, which is located on the Entry Motion page of a Dynamic Mill and OptiRough toolpaths’ parameters.

5. Safety Zone Motion Priority

A mesh-based safety zone always selects the shortest path of the sample slices but may have resulted in undesirable paths that do not consider the angle change.

To solve this, you can now also choose the path with the least angle change. Minimize angle generates paths with the least amount of angular change; Minimize length generates paths with the shortest distance between points; and Balanced generates paths that are balanced between the shortest distance and minimal angle change.

Want to learn more?

These are only a sampling of new features in Mastercam 2026. For more information, visit https://www.mastercam.com/solutions/products/mastercam-2026/ or visit https://whatsnew.mastercam.com for a complete list of all new features and improvements!