Programming the Future

How One College Is Impacting the Intelligent Manufacturing Pipeline

Blueprint for Success: Integrating Mastercam into SWIC’s Manufacturing Education

A hands-on precision machining program at Southwestern Illinois College (SWIC) is having a big impact on bridging the skills gap by training a new generation of digitally fluent, industry-ready programmers.

Overview

Challenge

Finding programmers and operators who can navigate a fast-changing tech stack with confidence

Solutions

Supporting education and workplace readiness

Results

Students graduate with hands-on experience in programming, machining, and advanced automation

Program Details

The Challenge

Today’s manufacturing environment isn’t powered by oil and elbow grease. It is driven by code, cloud connectivity, and complex machines. Artificial intelligence (AI) and intelligent manufacturing are operational staples.

At the same time, the industry continues to face a talent shortfall, and it’s not just about finding workers. It’s about finding programmers and operators who can navigate a fast-changing tech stack with confidence.

As technology keeps advancing, one question becomes mission-critical: How do we cultivate a generation of manufacturing programmers ready to thrive in a world where technology never stands still?

The Solution

To meet this challenge head-on, Mastercam is committed to supporting education and workplace readiness. By partnering with institutions like SWIC, Mastercam provides students and educators with the tools, software, and expertise that drive modern manufacturing.

The Benefits

Industry Readiness: Students graduate with hands-on experience in programming, machining, and advanced automation.

Sustainable Talent Pipeline: By producing its own educators and forming strong industry connections, SWIC has created a self-sustaining ecosystem for workforce development.

Accessible Education: With dual-credit options and low-cost community college tuition, programs like SWIC offer a fast, affordable path into a high-paying career.

Early Career Success: Graduates from precision machining programs like SWIC are in high demand.

Our program demonstrates the hunger for advanced machining skills. Students don’t just learn theory. Each semester, students design, program and physically machine their own projects.

From Three Students to a Talent Powerhouse

When Mark Bosworth took over SWIC’s program in 2008, he inherited a shop with three students, no CAM software, and a bare-bones manual setup. Fast-forward to today, and that same program boasts the following:

- Over 250 enrolled students

- Eight 5-axis machines

- Two state-of-the-art campuses

- A network of 12 dual-credit high schools

- Over 400 Mastercam licenses in use, including licenses for high school learners

What changed? Nearly everything.

The school began investing in modern equipment, forged deep partnerships with local industry, and of course, integrated Mastercam software. The partnership with Mastercam gives students access to industry-standard tools used across manufacturing, elevating classroom experiences to match professional expectations.

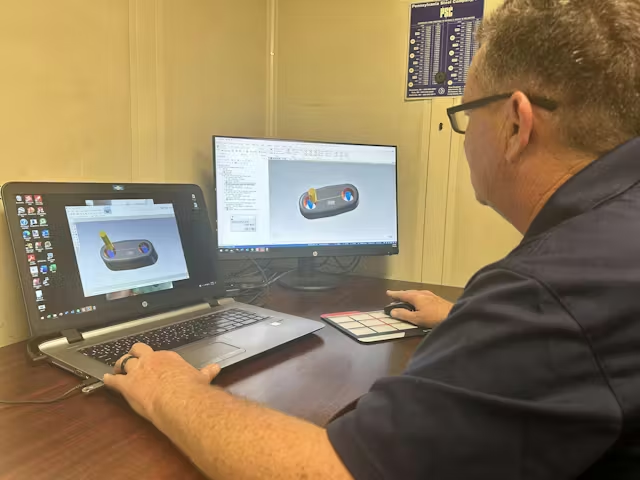

“Our program demonstrates the hunger for advanced machining skills,” says Bosworth. “Students don’t just learn theory. Each semester, students design, program and physically machine their own projects.”

Hands-on Learning

Students immerse themselves in hands-on projects, programming and machining parts inspired by their own passions, from rollerblade components to Darth Vader helmets. With roughly 20 hours a week spent operating machines and using CAM software, students gain a real-world rhythm and routine.

Bosworth emphasizes the importance of advanced training: “We’re not just teaching students how to operate machines, we’re giving them the skills to transform manufacturing. They learn to program, set up, and run 5-axis systems that can drastically improve production efficiency.”

Nurturing the Ecosystem

SWIC’s community-focused, industry-driven program has earned 18 national SkillsUSA medals since 2011, sending several students to nationals annually. These achievements boost student resumes and reflect program excellence.

The impact is tangible. Students often receive job offers before finishing the program with companies often competing for talent. SWIC works closely with employers to match students with part-time roles that offer real-world exposure. In addition, the program’s faculty is made up of SWIC graduates, creating a powerful cycle of mentorship and industry alignment.

That’s why we’re so committed at Mastercam to playing a key role in making this level of training possible with our industry-standard software and expert-level support. Because at the end of the day, even the best technology only works when people know how to use it and use it well.

3 Key Takeaways

- Early Engagement Drives Long-Term Impact

Integrating advanced software and industry tools into high school and college programs builds stronger, more confident students who are ready from day one. - Hands-On, Real-World Learning Is Essential

SWIC’s model proves that learning by doing creates job-ready graduates who adapt easily to manufacturing environments. - Partnerships Amplify Results

Programs like SWIC thrive because of strong partnerships. Mastercam’s advanced software and easy-to-use interface set students up for success.