Springfield Tech Inspires Young Students with Real World Tools

Steven Sinkwich, staff assistant at Springfield Technical Community College, hosts a summer camp for 12- to 17-year-olds every year. His goal is to spark an interest within the students in manufacturing not only to create future machinists but to teach the students creativity and independence.

Quick Facts

- Product Used: Mill, Multiaxis, Lathe

- Industry: Education

Project Details

- The Challenge: Sparking an interest for manufacturing and creating things in middle school and high school students.

- The Solution: Inspirational teachers using Mastercam

- Benefits:

- Easily learned and used.

- Most widely used CAD/CAM software in industry and education.

- Advanced simulation tools model every part of the machining process.

- Versatility and adaptability make many different projects possible.

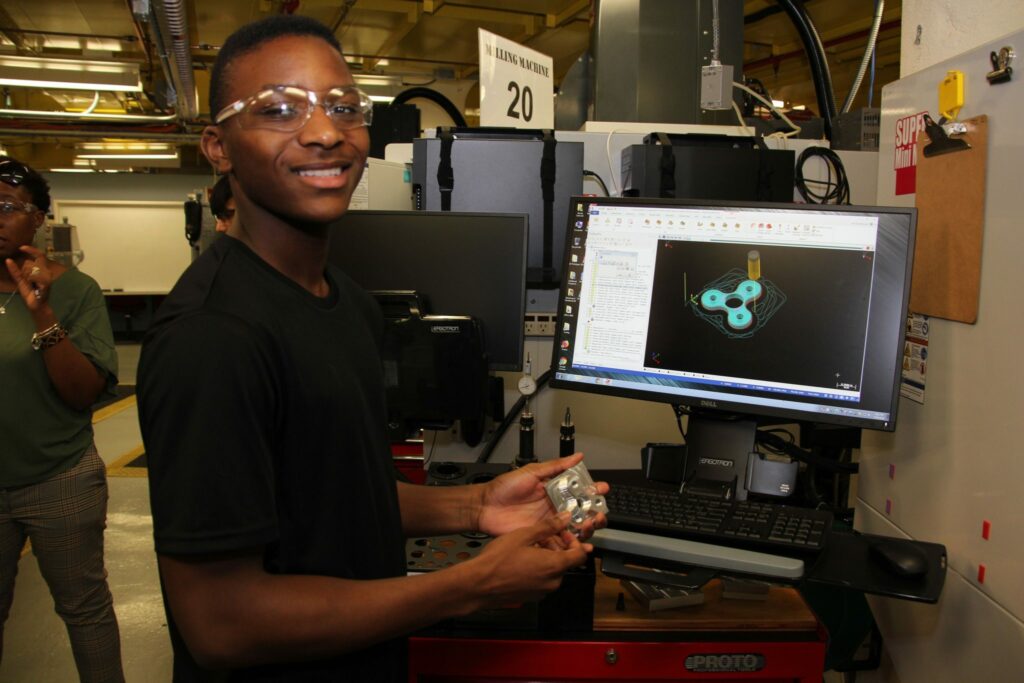

Sinkwich uses Mastercam to design and machine fidget spinners during the summer camp. He wants his students to be familiar with the most commonly used software, because that will best prepare them for their future careers.

“It seems that 90 percent of manufacturers are using Mastercam. I want them to go out and think, ‘Oh, we used that at summer camp.’ I want them to recognize it.” More than that, though, Sinkwich swears by the software’s advanced CAD/CAM capabilities. “It lets me visually show them a step-by-step operation of what’s going to happen when they’re at that machine. I get to show them how to face a part, how to do a contour mill. I’m showing them what the tool is actually going to do before they get to the machine. For the kids, it’s eye candy.”

With new students, being able to simulate the machining process is paramount to the learning process. Sinkwich relies on the Verify and Backplot features, which highlight mistakes and possible collisions in a simulation before machining ever begins. “Simulation shows all the mistakes and how to correct them,” he said. “It lets me see how the tools are going to work, and I can actually even prevent my crashes. When the kids get out there and press a green button, they’re not causing thousands of dollars’ worth of damage.”

The functions also saved Sinkwich time and material when he was originally programming the part. “The spinner is made in several operations. In the first operation, I grab my G54 in the corner of the part. I drill mounting holes for fixturing, contour the OD, and ream a center hole to be use on my second operation. When I flip the part over, I attach it to a fixture and use a probe to locate the center of the reamed hole as my new G55. Using a probe, the kids can see a bit more automation and blinking lights. After we move to the lathe where we turn the buttons for the fixture holes and bearing caps.”

He explains the process to his students as the machine runs. “I get to describe how that’s going, and I can show them I’m actually controlling my tolerances tighter, especially on the second operation, and sizing the hole for the bearing. Where a thousandth of an inch, a fourth of a human hair is too big, and the bearing falls through, a thousandth too small and the bearing won’t go in.” He explained that metaphors like this capture his students’ imaginations and inspire them to learn more about manufacturing.

“There’s a really cool project that we’ve been doing with our students for a while now,” says Parks. “My wife, Kathy, and I started and still coach our school’s mountain bike racing team, the Titans. Six years ago, our team of about twenty kids raced mountain bikes against teams from other schools in the area. The races are really hard and just finishing a race is a big deal for many of the kids. I thought it would be great if we could tell them, ‘If you finish the race, you get a medal.’ And, I thought, Why couldn’t my students make those medals? Today, six years later, we are still making medals for every kid who finishes the race. My students design the medals, program them in Mastercam, and produce them on our CNC machines.”

However, because they grew into such a large mountain bike team with most of the kids finishing each race, manufacturing cycle times became an issue. “Today, even though all the kids, even freshman, design the aluminum medals,” says Parks, “I have the seniors charged with the task of programming the medals in Mastercam for the lowest, most efficient cycle times, including the use of Mastercam’s Dynamic Milling feature ensuring fast, accurate tool paths. This is a good example of ‘real-world’ manufacturing, where time is money.

Customer Quote

“Simulation shows all the mistakes and how to correct them. It lets me see how the tools are going to work, and I can actually even prevent my crashes. When the kids get out there and press a green button, they’re not causing thousands of dollars’ worth of damage.”

– Steven Sinkwich, Staff Assistant at Springfield Technical Community College