Self-Starter Relies on CAD/CAM for Shop Success

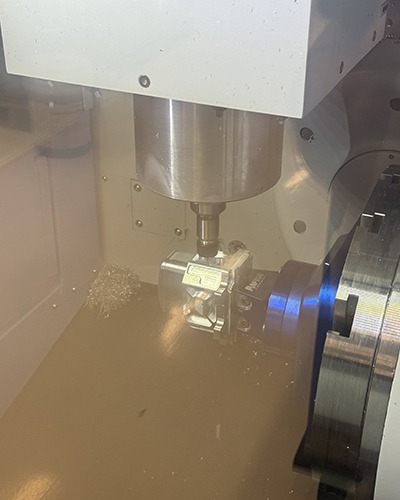

Innovative Technology Manufacturing uses Mastercam to run its CNC machines and produce complex parts for the aerospace and defense industries.

The Challenge

Producing complex parts to expand customer base.

The Solution

Mastercam, the most widely used CAD/CAM software for machining applications.

Benefits

- Unified Multiaxis toolpath brings more flexibility in cut pattern and makes finishing less complicated.

- Mastercam and 5-axis milling helps streamline manufacturing processes.

Project Details

A lifelong motorsport enthusiast, Matt Blankenship grew up in the automotive racing world. It was a family affair—his father was a hotrod builder and both he and his brother raced. At the age of 19, Blankenship transitioned from racing cars to building them when he landed a job as a fabricator with Hendrick Motorsports (Charlotte, North Carolina).

After several years of working for the race team, he came across a YouTube video produced by TITANS of CNC (Flower Mound, Texas). Blankenship had no CNC machining experience, but after watching several videos, he was hooked.

“I was so intrigued by the online videos that I decided to start a business. I was confident that I could find machining work,” he said.

While working full time at Hendricks, Blankenship purchased a Haas CNC lathe and started a machining business from his garage. Innovative Technology Manufacturing (ITM), Mooresville, North Carolina, was up and running on a part-time basis. After approaching several shops to promote his turning services, Blankenship discovered that nearly every shop he visited needed to outsource milling jobs, so he decided to expand his machining capabilities. He bought a mill and leased a commercial building. For the next two years, Blankenship built his customer base and, in August 2021, began working full time at ITM.

As jobs began requiring more set-ups, Blankenship purchased an additional 5-axis mill to streamline his machining processes. He learned multiaxis programming and machining with help from Mastercam YouTube videos and online tutorials and contracted a CNC programmer who recommended upgrading to Mastercam. Blankenship purchased the software and has not looked back. Now equipped with CAD/CAM software and multiaxis machining, ITM could handle parts that were even more complex.

The investment in CAD/CAM and the 5-axis mill paid off as a majority of ITM’s business comes from the defense and aerospace sectors. The company is now in its fifth year of business. Its 4300-square-foot production facility houses five CNC machines. Blankenship credits Mastercam with providing the capabilities to manufacture complex quality parts and avoid production inefficiencies.

One part that proved especially challenging to machine was a quick-change rear-end housing for the vehicle that holds the world’s fastest land speed record. Blankenship started with a 275-pound aluminum billet; the final part weighed in at 49.1 pounds. The part was too large for ITM’s 5-axis mill, so Blankenship had to get creative while surface machining.

“I was able to create planes then create surfaces using the Unified Multiaxis toolpath,” he said. “I used the surfaces as avoidance so I could actually machine this part inside the machine. The work envelope was not big enough. The only way to do it was with the 5-axis to hit these tight tolerances on these bearing bores and everything had to line up.”

The Unified Multiaxis toolpath combines the functionality of Morph, Parallel, Along Curve, and Project Curve surface toolpaths into a single interface, resulting in expanded and highly flexible cutter path creation. It lets programmers switch between machining strategies without having to rebuild from scratch. Unified brings more flexibility in cut pattern and makes finishing less complicated for the user, features that Blankenship appreciates.

“If I didn’t have Mastercam, I don’t know how I would have machined this part,” he said.

Quick Facts

- Product Used: Multiaxis, Mill 3D, Lathe

- Industry: Aeorspace & Defense, Job Shop, Metalworking

“If I didn’t have Mastercam, I don’t know how I would have machined this part.”

Matt Blankenship, Owner, Innovative Technology Manufacturing, Mooresville, North Carolina