Precision at Five Microns

How JWA CNC Precision Masters Manufacturing's Most Demanding Challenges

Blueprint for Success: Standardizing Excellence in High-Precision Manufacturing

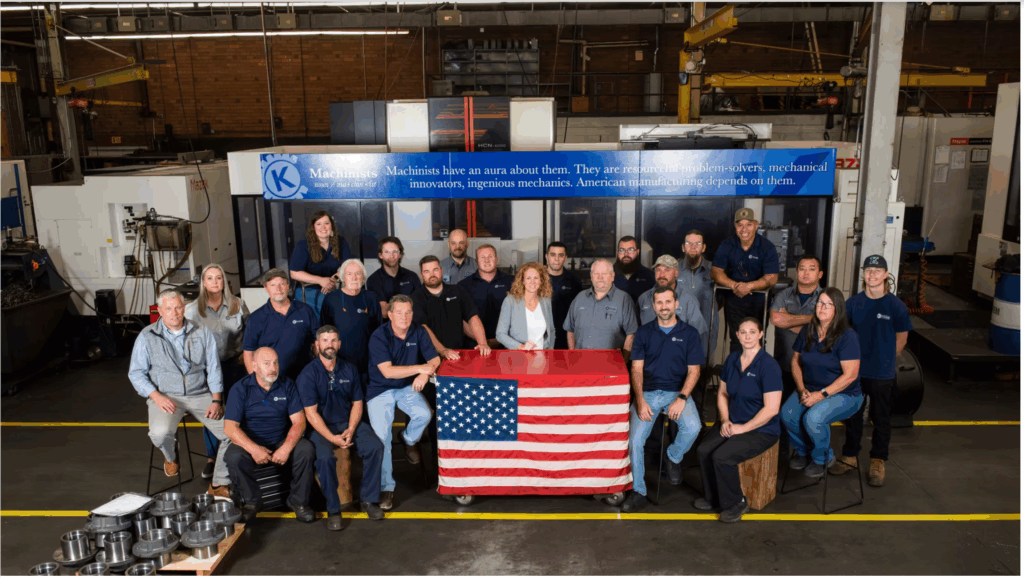

JWA CNC Precision, a precision manufacturing operation in the United Kingdom is proving that with the right CAM technology, even the most challenging tolerances and complex variations can be mastered consistently, efficiently, and profitably.

Overview

Program Details

The Challenge

Manufacturing precision components for aerospace, defense, and green energy isn’t just about hitting tight tolerances—though JWA CNC Precision routinely works to five microns. It’s about doing it consistently across an incredibly diverse product mix.

“We work predominantly with non-ferrous materials, small components, tiny tolerances,” explains Pete Wood, Managing Director. “There’s quite a lot of variation in what we do… most of our orders go out in a shoebox.”

The numbers tell the story: 9,000 different components in their catalog, with approximately 2,000 manufactured annually. Each requires precision machining of aluminum, stainless steel, plastics, and composites. Each demanding the same exacting standards that earned them AS9100 certification.

The real challenge? Maintaining consistency and efficiency across this enormous variation while minimizing downtime and waste.

The Solution

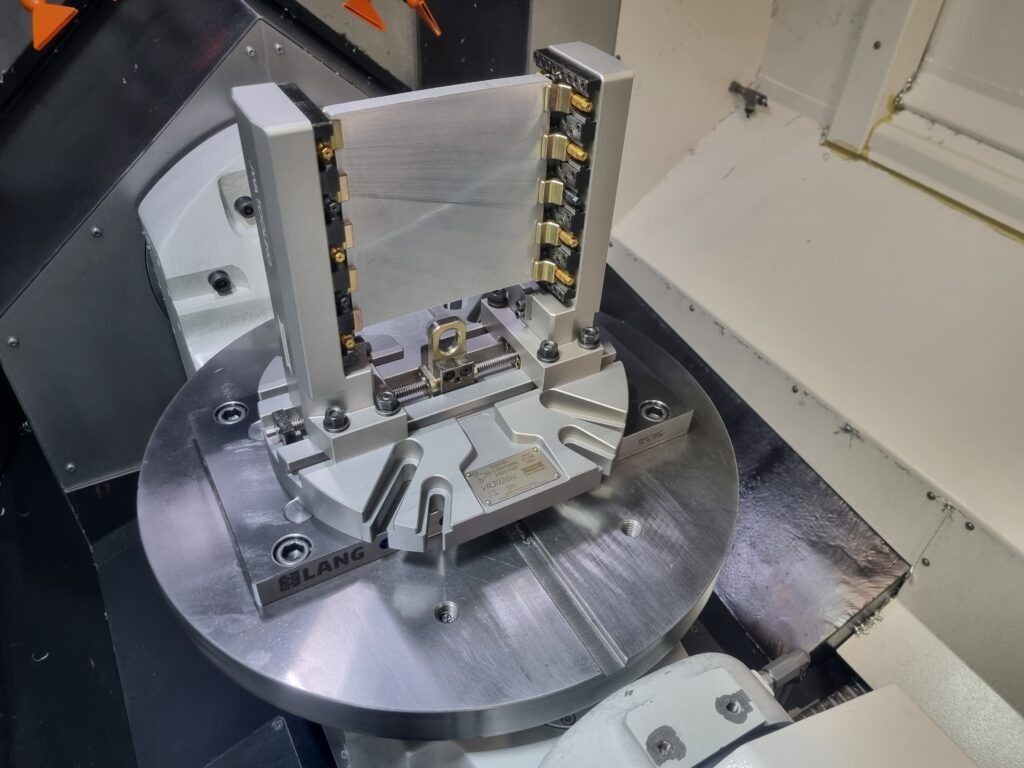

For over 20 years, JWA CNC Precision has relied on Mastercam as what Pete Wood calls “the heart and soul of our manufacturing infrastructure.” But they’ve gone beyond simply using the software, they’ve created a comprehensive system around it.

Technical Director Tim Shillabeer, who brings decades of CAM experience across multiple platforms, chose to stick with Mastercam for practical reasons: “One of the great things about Mastercam is it’s so widely used, there’s a lot of information and a lot of help available.”

The Benefits

Operational Consistency: Standardized programming and setup procedures across all operations ensure any trained operator can seamlessly handle work.

Scalable Training: New hires can become proficient within days through Mastercam’s training infrastructure, with annual refresher courses keeping the team current.

Reduced Downtime: Consistent programs and setup sheets significantly narrow gaps between jobs, directly impacting productivity.

Flexibility at Scale: The system handles everything from one-offs to medium batches with equal efficiency.

"Whatever challenge we're faced with, Mastercam sits there with all its defaults and libraries so that we can directly dive onto that challenge and meet it very quickly".

The Drive to Consistency

The transformation didn’t happen overnight. As Shillabeer explains, “I think the biggest benefit to us of having been a long-time user of Mastercam is that we’ve ironed out so many little nuances that work for us.”

What started as a necessity became a competitive advantage:

- Standardized Processes: Every operator follows the same structured approach, ensuring consistent results regardless of who’s running the job.

- Eliminated Waste: Systematic programming reduced hours lost to setup variations and programming inconsistencies.

- Rapid Response: “Whatever challenge we’re faced with, Mastercam sits there in its current condition with all its defaults and libraries so that we can directly dive onto that challenge and meet it very quickly”.

Advanced Users, Proven Results

JWA CNC Precision describes themselves as “quite at the advanced end of the scale” when it comes to Mastercam usage. This expertise, combined with the software’s robust capabilities, has enabled them to:

- Achieve AS9100 certification for aerospace and defense work

- Maintain tolerances as tight as five microns across diverse materials

- Scale operations without sacrificing quality or efficiency

- Build a training system that creates interchangeable, highly skilled operators

The impact extends beyond just programming. As Wood notes, the standardization “really has helped in the downside between jobs and it really has taken impacts on wasted hours.”

3 Key Takeaways

- Standardization Drives Efficiency: Creating consistent processes around advanced CAM software eliminates variation and reduces waste across operations.

- Training Infrastructure Enables Scale: Mastercam’s widespread adoption and training resources allow rapid workforce development and seamless knowledge transfer.

- Long-Term Partnership Pays Off: Over 20 years of experience has allowed JWA CNC to optimize their use of Mastercam, creating customized workflows that deliver competitive advantages.