Mastercam’s Dynamic Motion Control Helps Titletown Score Championship Machining Reputation

Green Bay, Wisconsin is a multi-million dollar center of manufacturing for the paper industry. For 60 years, Titletown Manufacturing LLC has been one of the biggest suppliers of precision machined components to fulfill the production needs of OEMs in this sector.

Quick Facts:

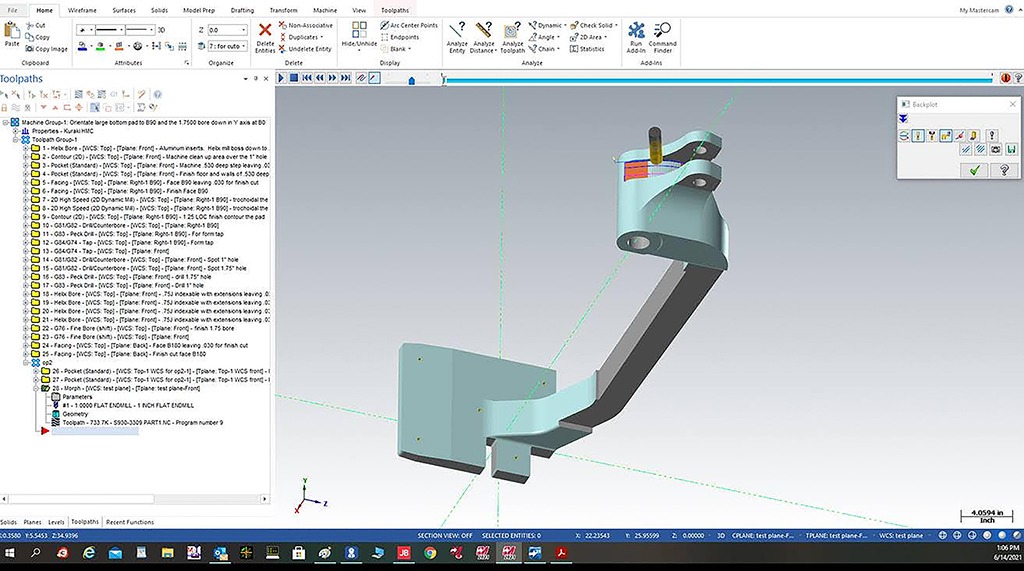

- Product Used: Mastercam Mill, Multiaxis

- Industry: Paper, Machinery

Project Details:

- The Challenge: Titletown Manufacturing needed to attract and retain young, skilled talent and challenged itself to take on new and difficult jobs to maximize its investment in machinery and tools as well as its employees’ talents.

- The Solution: Mastercam CAD/CAM Software

- Benefits:

- Ability to program and manipulate 3D images in the software.

- 2D Dynamic toolpaths allow machines to run at maximum feeds and speeds for shorter lead times.

- Flexibility allows programmers to be creative when finding solutions to complex geometries.

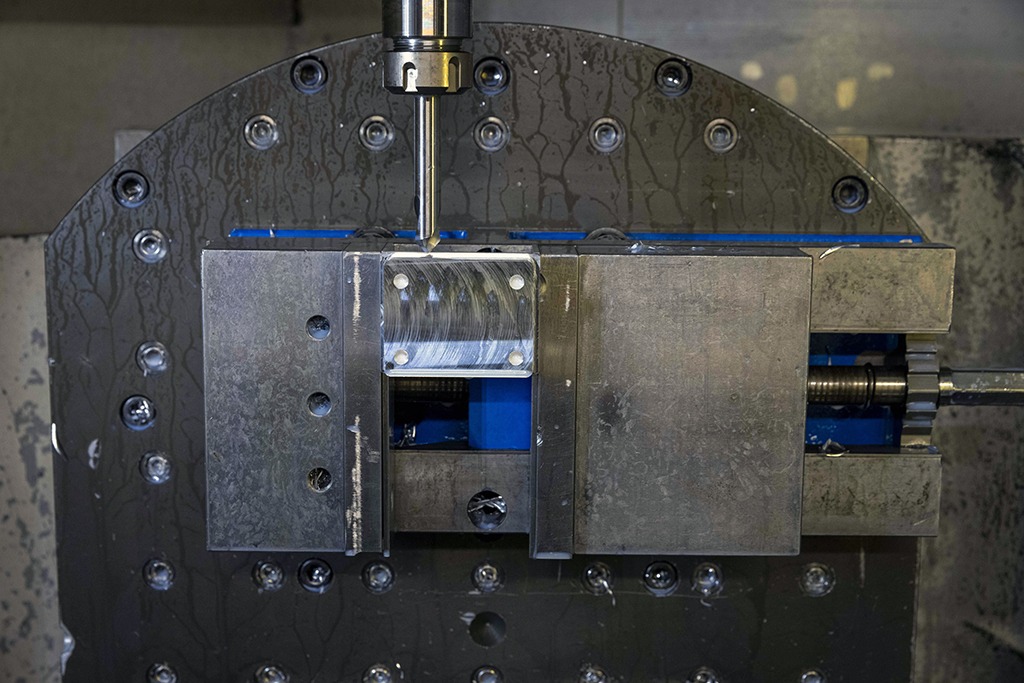

“A lot of our parts go into OEMs that do things such as paper converting, banking equipment, frames, rolls, brackets, really anything that fits in our wheelhouse,” explained Operations Manager Tim Sanders. “We are not afraid of much around here. Paper converting, packaging equipment, and any component that would go into bagging equipment from a roll to a bushing to a bearing block.”

The company’s 30 or so employees operate in an environment that is unique in precision-driven industrial companies with high perfectionism and low tolerance for shortcuts.

Titletown operates a shop with a wide range of metalworking and fabrication machinery, from seven Mazak vertical milling machines including the Variaxis 630-5X 5-axis; Mazak and Kuraki horizontal millers and boring machines; Mazak, Clausing, and Southbend turning lathes; Churchill, Norton, and Sonnen grinding machines; and a Blanchard and Kent surface grinder.

Complex geometries and an increasing demand for a variety of components are made possible with Mastercam. For Tim Sanders and Titletown Manufacturing, precision and flexibility are the most robust attributes.

“We have Mastercam Mill with Multiaxis for one of our Mazak Variaxis machines. We do mostly 3 + 2 machining on there,” Sanders said. “Mastercam is so flexible that we can run it on the Kuraki, we can run it on the 5-axis, we can run it on the horizontal or on the vertical and get the same results. I have used other software, but nothing is as powerful as this.”

Sanders said the ability to produce non-standard jobs without having to invest in expensive, single-use tools is an additional benefit of using Mastercam. Using 3D programming capabilities to set up a machine to run unattended — even achieving complex geometries — like in a recent demanding job that pushed Titletown machines with feeds and speeds that made its machinists sweat. Simultaneous 5-axis machining enables Titletown to complete more operations in a single cycle, avoiding the need to reposition parts and holding tolerances to +/- 0.0001 inch. One such part was a skid plate for an outrigger.

“It was made from an abrasive material and this particular part had a weird angle. It had a 60-degree bevel, but the hypotenuse might have been three inches. Instead of stepping down a 60-degree tool, we 3D milled it. The part also had a 1 1/4-inch radius. Instead of buying a gigantic ball end mill, we 3D milled the part with a seven-flute bull nose end mill from MA Ford. We were pushing that at 300-inches-a-minute and had the spindle maxed out.

Because of the software, we were able to incorporate, A, that ball end mill, and B, that bevel tool. There was actually another radius and chamfer on that tool that we could complete all with Mastercam because of their 3D toolpaths, and all at a super high rate of speed. It works well.”

Titletown’s Mastercam Reseller, ShopWare, Inc. (Elgin, IL) has played a part in helping Sanders and his team learn more about the software and navigating new and unusual jobs.

“The entire team at ShopWare is fantastic,” Sanders said. “They have helped me immensely and there is usually somebody available that can take care of whatever you need. I can say nothing but good things about the people working at ShopWare, that’s for sure.”

The combination of machinery and Mastercam enables Titletown to be creative — especially negotiating complex geometries.

“I like to think we can compete with anybody and certainly the software allows us to do that,” Sanders said. “Also, it’s a pretty good recruiting tool when you can show some young people and personnel what they can do with the software.”

The versatility of Mastercam enables Sanders and his machinists to push capabilities and manipulate toolpaths. The key is Mastercam’s 2D Dynamic Milling which provides constant chip loading. Proprietary algorithms programmed into the software detect changes in the material, allowing the endmill to be constantly engaged with the material and automatically adjusted as needed. Lead-in cuts are kept to a minimum, resulting in fewer tool and material breakages. Because the entire length of the flute can be used, machines can literally plow through material at higher rates of speed.

Titletown Manufacturing’s forward-thinking approach to manufacturing, from its people to the technology they use, has helped to put it in victory formation for a successful future.

Customer Quote

“I like to think we can compete with anybody and certainly the software allows us to do that,” Sanders said. “Also, it’s a pretty good recruiting tool when you can show some young people and personnel what they can do with the software.”

– Tim Sanders, Operations Manager, Titletown Manufacturing, LLC