CAD/CAM Software at Center of Experiential Learning

Rensselaer Polytechnic Institute (RPI) has been educating innovators and influencers since 1824. Its faculty and alumni have long been leaders in biotechnology, nanotechnology, computational science, and engineering research and development.

Quick Facts:

Product Used: Educational Suite, Multiaxis

Industry: Education, Plastic Injection Molding, Metal Forming

Project Details:

- The Challenge: Understanding manufacturing processes and possibilities without damaging equipment or wasting resources.

- The Solution: Mastercam, the most widely used CNC software for CAD/CAM operations.

- Benefits:

- Mastercam simulation functions support Smart Measure and improved toolpath processing.

- Mastercam’s simulation tools enable experimentation, so students can find the most effective processes.

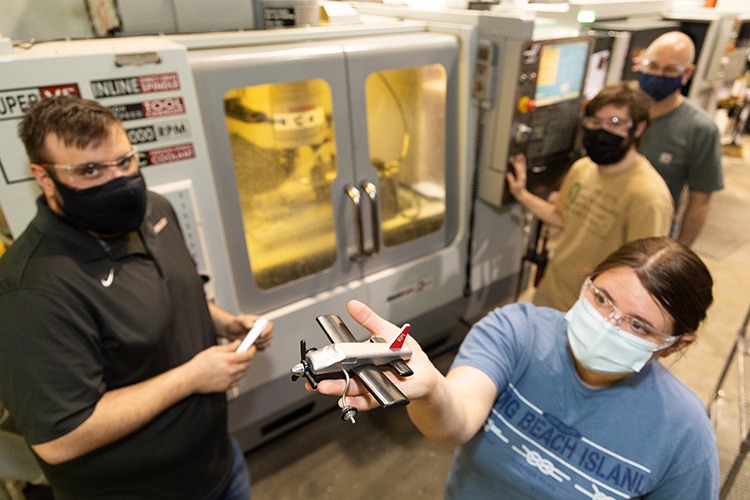

Located in Troy, NY, the RPI School of Engineering offers 11 undergraduate and 19 graduate degrees in its seven departments, and Sam Chiappone is the school’s director of manufacturing innovation. He has taken RPI’s mantra of transitioning technological advances into the marketplace to heart to ensure RPI manufacturing classes and facilities are ahead of the curve for industry.

Chiappone, and the faculty and staff he collaborates with, are responsible for helping future engineers move from theory to practical application. Mastercam CAD/CAM software is a trusted component in the classroom and in the laboratory.

“We look to work with industrial partners like Mastercam and a number of different industrial partners to evaluate our programs so the content is on par with what’s happening in industry.”

Mastercam is used in the introduction to Computer-Aided Machining class, as well as the Manufacturing Processes and Systems class. This senior-level mechanical engineering class involves students designing and planning the manufacture of a widget assigned to them by faculty. The class runs competition style, starting with 48 students split into teams of four in the fall. After presenting their solutions, the top two teams move on to the advanced class in the spring.

The widget could be anything from a model of a Ferris wheel to a yo-yo. Students must determine how to use different manufacturing processes to make a specified number of products. Students perform engineering analysis and go through lab exercises related to the various processes needed to get the job done.

RPI’s forward-looking manufacturing learning environment is the Manufacturing Innovation Learning Lab, or MILL. The facility is outfitted with an array of CNC machining equipment as well as robotic manufacturing and plastic injection molding machines.

The MILL also supports RPI’s senior capstone projects that enhance the experiential learning process even further.

Students are assembled into teams to solve the problems presented to them. If something has to be machined or students need to use a robot or other manufacturing resources for a project, the MILL and its staff is there to support them. According to Chiappone, of the strongest tools in their toolbox is Mastercam.

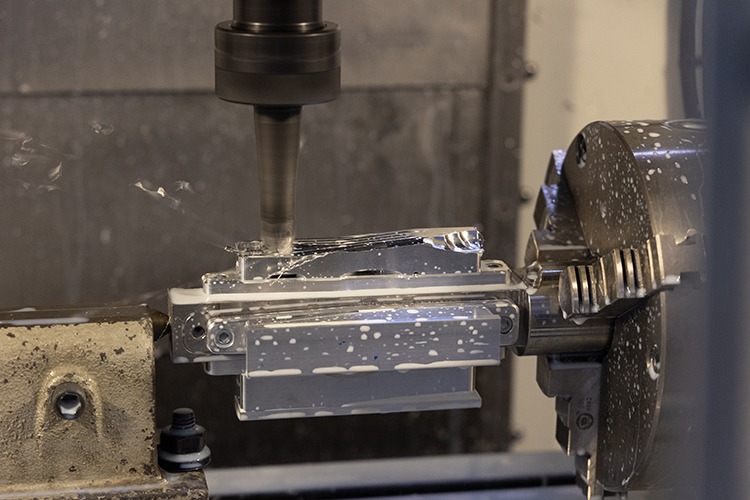

“The big push in industry is simulation,” he said. ““We knew that it was critical that we start showing engineering students how simulation is used in manufacturing to give them a foundation in that area…Mastercam played a big role in that.”

Mastercam’s simulation tools allow users to experiment and find the most innovative and efficient fixturing and cutting possibilities without damaging equipment or wasting resources. In the latest version of Mastercam, powerful simulation functions support Smart Measure and improved toolpath processing. Designed to save time during program verification, Smart Measure confirms work with accurate point-and-click measurements. Improved toolpath processing times yield faster, more responsive simulation data handling.

Customer Quote

“We look to work with industrial partners like Mastercam and a number of different industrial partners to evaluate our programs so the content is on par with what’s happening in industry.”

— Sam Chiappone, Director of Manufacturing Innovation for the School of Engineering, RPI, Troy, NY