CAD/CAM Software Helps Students Experiment with Toolpaths, Cycle Times

Kyle Sisco, a Machining Instructor at Ogemaw Heights High school in West Branch, MI, is a hands-on teacher. His curriculum is centered around students using and doing as soon as possible.

Quick Facts:

Product Used: Educational Suite

Industry: Education, Aerospace

Project Description:

- The Challenge: To produce parts for research on the International Space Station.

- The Solution: Using Mastercam, the students created and adjusted the toolpaths and processes they needed to accomplish their goal.

- Benefits:

- Verify helps students ensure their chosen toolpaths will work as intended.

- Backplot gives students a realistic look of what their machining processes will look like.

As his students advance through Ogemaw’s machining program, Sisco finds real-world jobs for them to complete.

“They have to know the entire process,” he said. “I want them to know the reality of making parts—from planning through inspection.”

To do this, Sisco casts a wide net to find classroom projects, co-op learning opportunities, and jobs. One such search brought him to the NASA HUNCH (High Schools United with NASA to Create Hardware) program, which gives high school students educational experiences by producing research items for the nation’s space program.

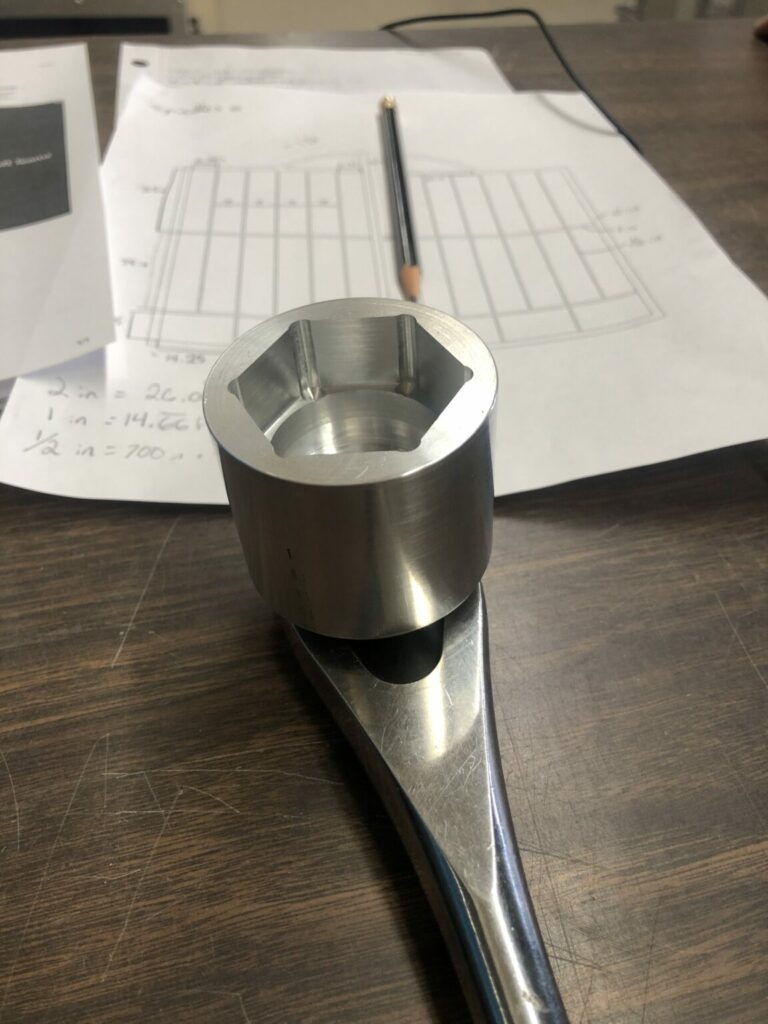

Ogemaw won a NASA HUNCH project to create a part for experiments on the International Space Station. NASA sent an order for 50 pieces along with prints and materials. Sisco handed everything over to his students, offering guidance only when asked.

The students used Mastercam to create processes and toolpaths, then narrowed down their choices to the three best. They used Verify and Backplot along the way to make sure they were on the right path.

“It was the kids programming it, setting it up, and inspecting it,” said Sisco. “They did everything. My role was basically as a liaison between my students and the folks at NASA.”

The students produced 62 parts in their first run, using only one of the four bars of material they were given. Sisco contacted the NASA HUNCH program manager to find out what to do with the extra material. The program manager, pleasantly surprised, told them to run additional parts.

Ultimately, the Ogemaw students made 200 parts, with 100 percent of them passing inspection. NASA was so impressed, a program director came from Houston to meet the students, who were thrilled. They may be used to teachers and local machine shop owners coming to visit, but a NASA engineer was something else entirely.

“The kids loved getting to show off what they did,” said Sisco.

Projects like NASA HUNCH give students an exciting look into how they will use their skills after graduation. Sisco’s goal is to make sure his students are turnkey graduates, able to walk out Ogemaw’s door and into any machine shop, large or small, ready to go.

One of their most important skills is CAD/CAM programming. Students quickly find Mastercam’s Verify module is one of their most useful tools. Verify allows users to view finished shapes of parts and visualize fixtures. Problems are addressed before parts are cut, resulting in increased productivity.

“Once you learn the software, it’s just a matter of connecting the dots between what you want to make and how you go about it,” he said.

Sisco encourages students to always consider improving part quality and cycle times. Mastercam’s Dynamic toolpaths enable this kind of critical thinking and continuous improvement by letting users test new ways to run parts. With Mastercam, curious young students have the opportunity to question, experiment, and learn while being smart with materials and resources.

All of Sisco’s students graduate with the skills they need to be turnkey employees, including how to use CAD/CAM software to create efficiencies to save both time and money.

Customer Quote

“They have to know the entire process. I want them to know the reality of making parts—from planning through inspection.”

— Kyle Sisco, Machining Instructor, Ogemaw Heights High School, West Branch, MI