M2C Racing Takes Advantage of Swiss Machining to Make What a Regular Lathe Can’t

When M2C Racing decided to take its Swiss parts in-house, it needed to find the best way to run its new Star Swiss screw machine. That solution was Mastercam CAD/CAM software, backed by expert partners and its own knowledgeable engineers.

Quick Facts:

- Product Used: Swiss Solution

- Industry: After Market RC parts manufacturer

Project Details

- The Challenge: Producing the world’s best aftermarket RC parts on a Swiss machine without wasting time fiddling with faulty posts or messy programming.

- The Solution: Mastercam, the most widely used CNC software for machining applications

- Benefits:

- Network of knowledgeable, experienced Resellers who can introduce and explain new techniques and functions.

- Partners like Postability are ready and eager to share their expertise and help in areas like creating post processors.

- All Mastercam products use the same basic interface, making learning easy.

- Mastercam Swiss offers intuitive, powerful Swiss machining solutions to make programming simple.

M2C Racing is the world’s largest aftermarket remote control vehicle parts manufacturer, specializing in parts that can take a bashing. “What sets us apart from the other companies is that we developed a group of testers,” said owner Avery Looper. “They go out there and they beat these cars as hard as you could possibly beat them. Then we listen to them and make the changes needed to produce the best parts on the market.”

These testers jump their RC cars over 95 feet into the air and 200 feet or more across ditches, and then the testers report back to M2C about what loosened or broke so that M2C can find a solution. “This way, we know that each one of our parts is the toughest on the market,” explained Looper. Because of this dedication to quality, M2C Racing exploded from a hobby shop to the RC part industry’s leader.

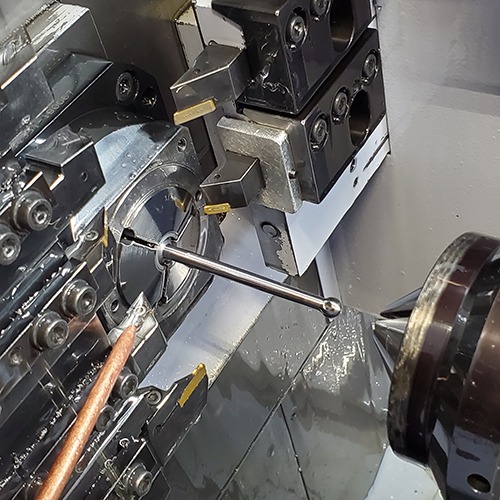

M2C Racing had historically contracted out its Swiss work, but the time came when this was no longer profitable. Looper purchased a Star SR38 type B 10-axis screw machine and – after a failed attempt with a different software suite – paired it with Mastercam CAD/CAM software. Experts from CNC Software, LLC and their partner, Postability, set Looper up with the perfect NC post processor for the job.

M2C Racing went from having absolutely zero production in its Swiss department to producing new parts on a weekly basis. Unlike many screw machine shops, M2C produces short run parts and an imposing amount of prototypes. “We set the machine up for a new part on a weekly basis – with changeovers using the same size material, sometimes we set up a new part three or four times in a week.”

Looper shared that part of this success relies on the POCO routine, or the pick-off/cut-off operations. “With POCO, you can just click the solid and the software will automatically generate the cutoff sequence, with the second head coming in and picking it off. It’s all one click. After that, it will simultaneously run the backside operations in the sub-spindle while machining your next part in the main spindle, automatically.” Swiss machining has completely changed how M2C is able to machine drive shafts, which are now a sizable portion of its sales.

Although Looper came to M2C Racing with decades of experience with Mastercam Mill from his time in aerospace, he had barely any experience with Lathe and none at all with Swiss. Luckily, the intuitive interface and his extensive support system made the transition seamless.

“In just a couple of months, I’ve gotten to the point where I can do almost anything that will fit on this screw machine,” he said. “I’m so confident, I just ordered another Star SB20R. I have no doubt I can make anything.”

Customer Quote

“In just a couple of months, I’ve gotten to the point where I can do almost anything that will fit on this screw machine.”

— Avery Looper, Owner, M2C Racing, Leduc, Edgemoor, SC