Area Teens Offered Advanced Manufacturing Program

Sunnyside, Arizona’s Desert View High School is located in an area heavily populated by lower-income Latino immigrants. Students have found opportunities and diverse career paths through the school’s Advanced Manufacturing Program and the efforts of its dedicated teacher, Cesar Gutierrez.

Quick Facts:

Product Used: Mastercam Educational Suite, Dynamic Motion

Industry: Education

Project Details:

- The Challenge: Building a successful Precision Manufacturing program for high schoolers that prepares them with the skills for real-world manufacturing and provides them with a variety of job opportunities.

- The Solution: Mastercam Educational Suite, Strategic Partnerships

- Benefits:

- User-friendly platform for students to learn

- Support from Mastercam experts in education and industry

- Experience using the most widely used CAM software in manufacturing

Desert View High School in Sunnyside, Arizona, offers area teenagers the opportunity to obtain not just a quality education, but also to take the first steps toward a rewarding career in advanced manufacturing. It should be noted that Desert View High School is rooted in a primarily low-income Hispanic community. Jobs beyond those considered minimum wage were once few and far between.

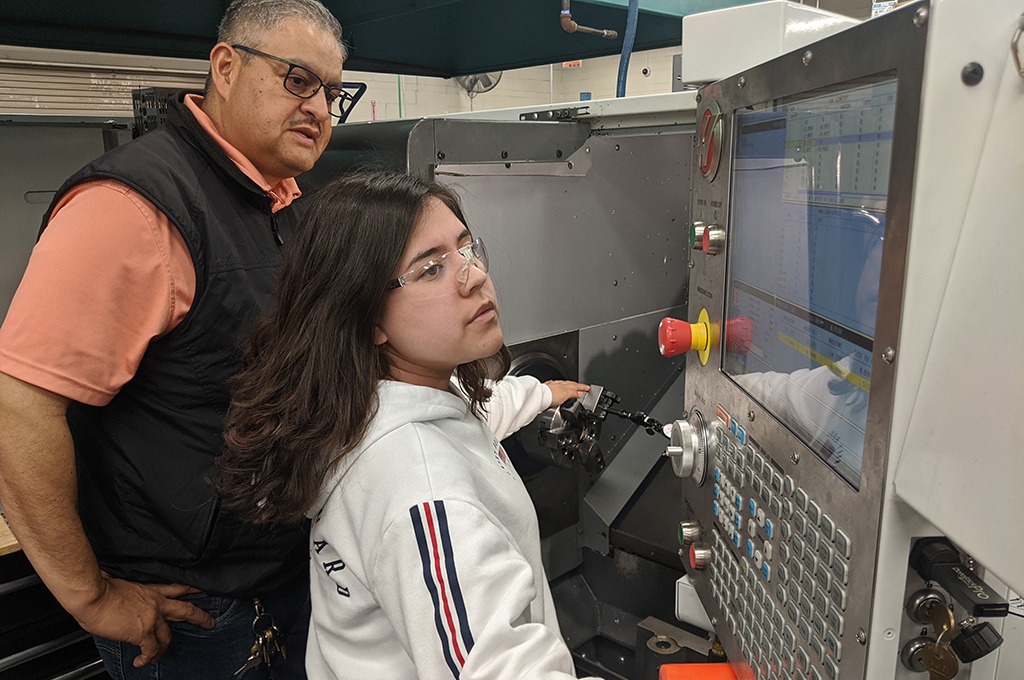

Cesar Gutierrez, the school’s Precision Manufacturing teacher, set out over four years ago to create a CAD/CAM program designed to attract students and hold their interest through graduation and beyond.

Gutierrez engaged the local manufacturing community to help. “There are 42 manufacturing companies in Arizona’s Pima County area that came together as Southern Arizona Manufacturing Partners to promote their industry among students, teachers, and parents,” says Gutierrez. “They found that senior employees were retiring and there was not enough of a potential labor force to replace them.”

“The Partnership representatives were serious about challenging our kids to follow a path to a rewarding career, while also assuring their own business future.” They introduced Gutierrez to a program developed by the National Institute of Metalworking Skills (NIMS) comprised of a series of manufacturing-related courses, including CNC machining, Industrial Technology Maintenance (ITM), and Computer-Aided Manufacturing (CAM) programming for CNC mills and lathes.

“I was assured that by using Mastercam for the CAM courses, I would be exposing our students to the software programs they would most likely encounter in the industry,” says Gutierrez. “Our Partnership owners and managers also advised me as to the operating functions to look for when obtaining CNC machine tools for our school’s shop.”

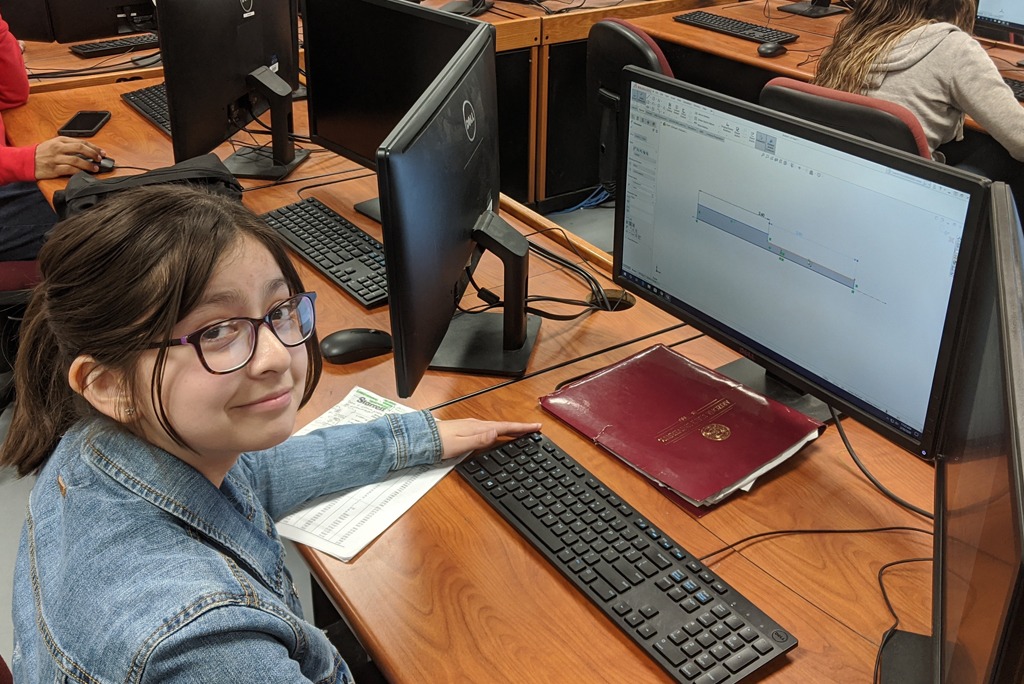

“Freshmen are introduced to the program in a summer session, where they become familiar with the operation of manual machines. In the fall they learn how to design an easy project with SOLIDWORKS®, then how to import the design into Mastercam to program the toolpaths, including basic toolpaths for contours and pockets and how to set up apart the correct way. In the second year, they get into Mastercam’s High-Speed Machining, how to ‘trick’ the machine, how to cut different arcs in different planes. In the third year, they learn how to program in four axes for the CNC mill. Next, they learn how to program up to four axes for the CNC lathe and in five axes for the CNC mill.”

The students earn NIMS proficiency certification in various operations as they advance in the program. “Mastercam, SOLIDWORKS, and NIMS are the three basic ingredients for the success of this program,” says Gutierrez. “Keith Butzgy, Technical Training Content Developer at Mastercam, and David Morgan, Senior Advisor at NIMS, have always been available to help me as our program expands to cover a wide range of projects for our CNC machines.”

Gutierrez adds, “Because of the faith in our program by our principal, our Career and Technical Education coordinator, and our district, we have been funded with nearly two million dollars for equipment. A great deal of the tooling for the machines and material for student projects comes from the generous donations of the Partnership members.”

The school has established a contract business with many of the Partner businesses who assign contracts to the Precision Manufacturing department, much as they would with any contract machining shop. “The students earn money to cover the expenses of the field trips we take to colleges, universities, and manufacturing companies all over the country,” says Gutierrez. “Some of the part runs are in the hundreds, a few even in the thousands. We have even delivered assemblies after machining the parts on our CNC mills and lathes and then joining them with our shop’s press.”

The school’s internship program provides seniors with a paycheck for work they contract. “It’s run as an actual business,” says Gutierrez. “They have to become involved in sales in order to get the business from outside sources, handle invoicing, and keep the books. By having a hands-on approach to subjects beyond programming and machining, they are becoming even more valuable to prospective employers.”

Many of the students go directly into industry from technical education at Desert View High School, others continue working part-time while they are in college. These students become empowered with a college degree, NIMS certification, and a foothold on a rewarding career.

Customer Quote

“I was assured that by using Mastercam for the CAM courses, I would be exposing our students to the software programs they would most likely encounter in industry.”

—Cesar Gutierrez, Precision Manufacturing Teacher, Desert View High School, Sunnyside, Arizona